Cim200 - Bill of Materials - Enhancements

Ensuring Consistency and Quality with Greater Control Of Manufactured Products

Enhanced Bill of Materials Software for Sage 200

With Cim200 Bill of Materials enhancements, an extension of the functionality of Sage 200 Bill of Materials, manufacturing businesses can operate in a way that works for them.

In addition to the Sage 200 Professional Bill of Materials functionality, Cim200 includes the following enhancements:

Ensure Efficiency is Built into Manufacturing Processes

Implement multiple routes and percentage bill of materials features to provide agility across production and warehousing.

Track Changes to Bill of Materials

Providing complete visibility, monitor and review all amendments carried out by users at field level within an audit log.

Maintain Accurate Stock Control

Employ advanced reverse build and kit bill of materials features to ensure accuracy of stock control is maintained at all times.

Cim200 & Sage 200 Bill of Materials

Additional Cim200 features have been added to the Sage 200 Bill of Materials module to enhance your manufacturing build processes. New functionality has been added to improve production efficiencies in multiple manufacturing environments. A production line environment can take advantage of multiple routes, enabling you to react to changing demands on your production lines and maximise output. Food, chemicals, and ingredient-based manufacturers can utilise Cim200 Percentage Bom functionality to ensure production accuracy. Kit Bom functionality enables assembly environments to streamline kitting and despatch processes.

As with all Cim200 modules, any additions or amendments have been created using the Sage 200 user interface, resulting in a seamless integration.

Included In Our Cim200 Bill of Materials Enhancements

-

Kit BOMs

- Multiple Routes

- Percentage BOMs

- Adhoc Reverse Build

- Base Items

- Audit Log

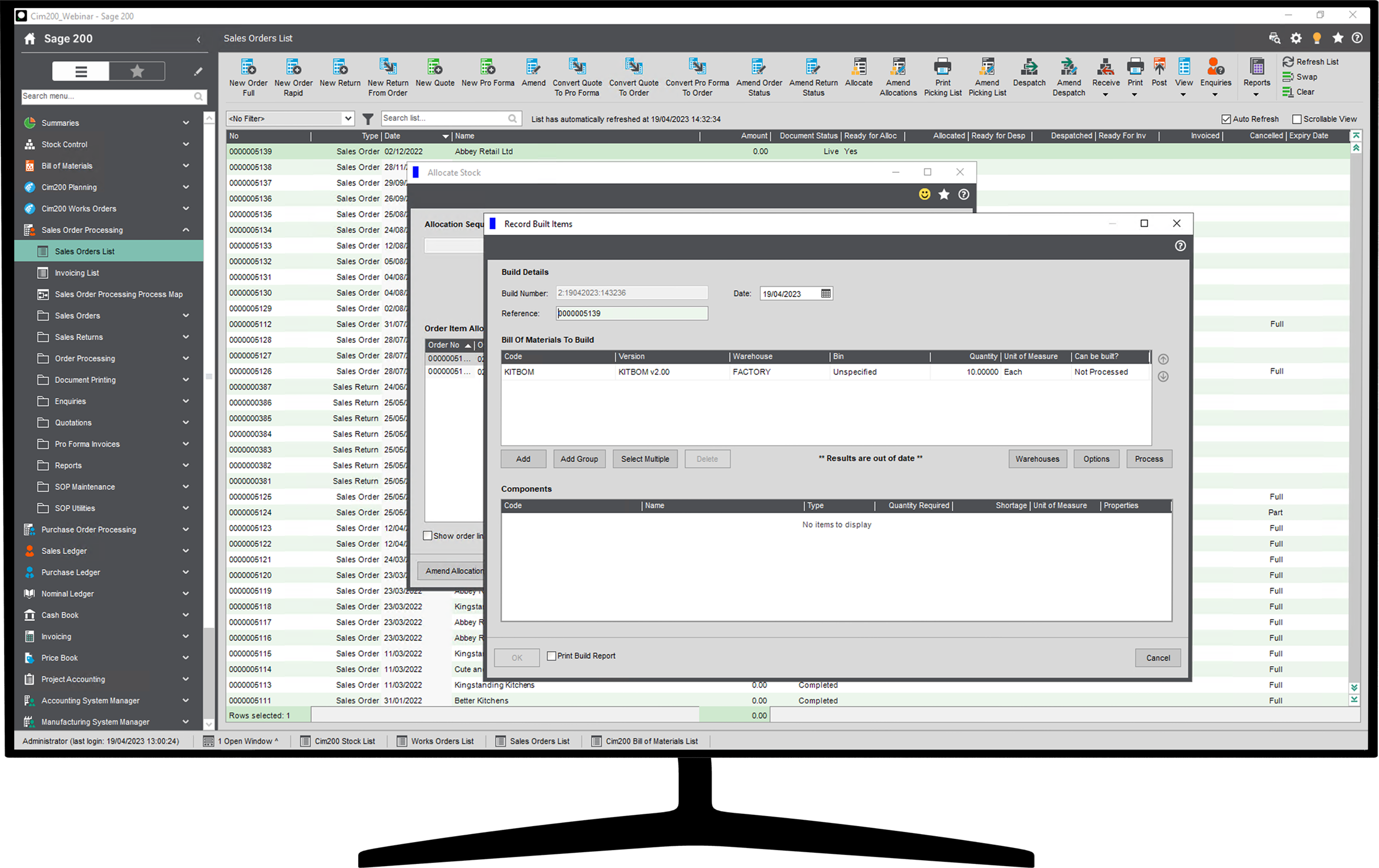

Kit BOMs

Kit BOM functionality enables you to efficiently assemble a kit of parts ready for despatch to a customer.

Complete a BOM build, adjusting out all of the component items from stock and booking the kit item into stock during sales order allocation, streamlining your order processing and data entry overhead.

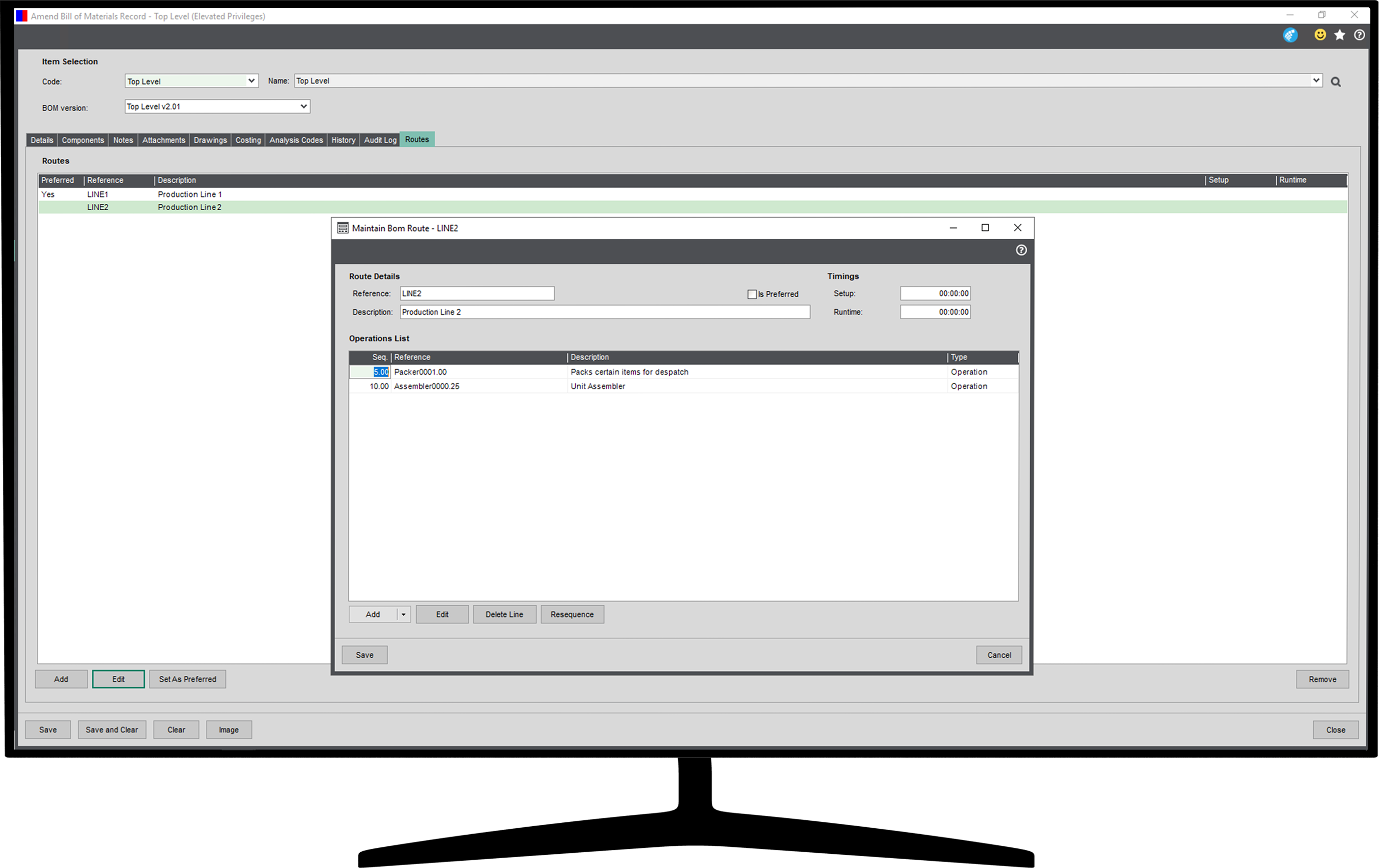

Multiple Routes

Giving you the flexibility demanded by agile manufacturing environments.

Multiple routes functionality enables you to define the different manufacturing processes on the Bill of Material, and then enables you to select the most appropriate route at the point of generating your Cim200 Works Orders, which could be based on available resource capacity, sub-contractor availability, cost or lead times.

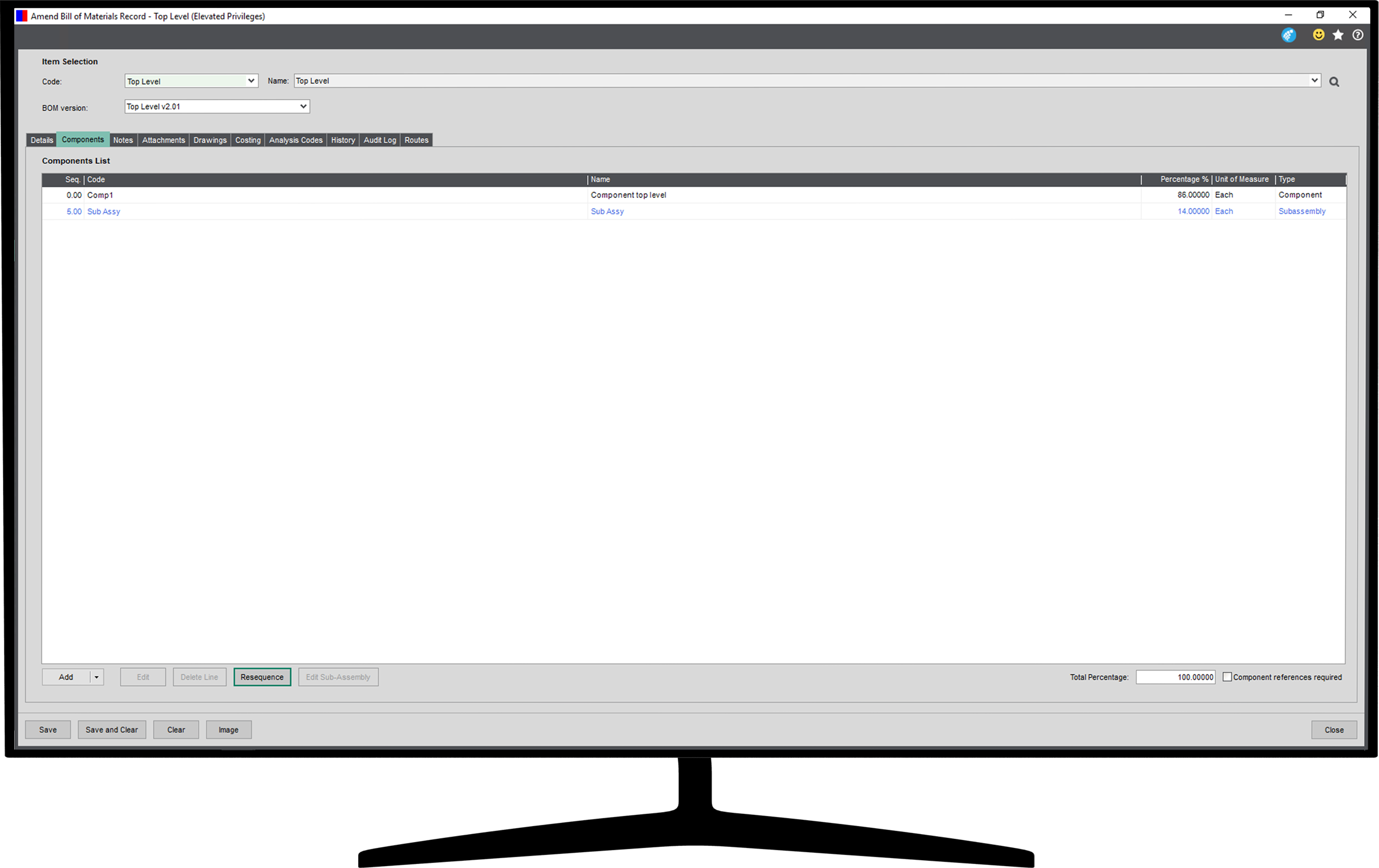

Percentage BOMs

Specifically designed for food and liquid/chemical manufacturers, have your manufacturing system work the way you do.

Cim200’s percentage BOM functionality will allow you to configure your Bill of Material components as a percentage of the finished product.

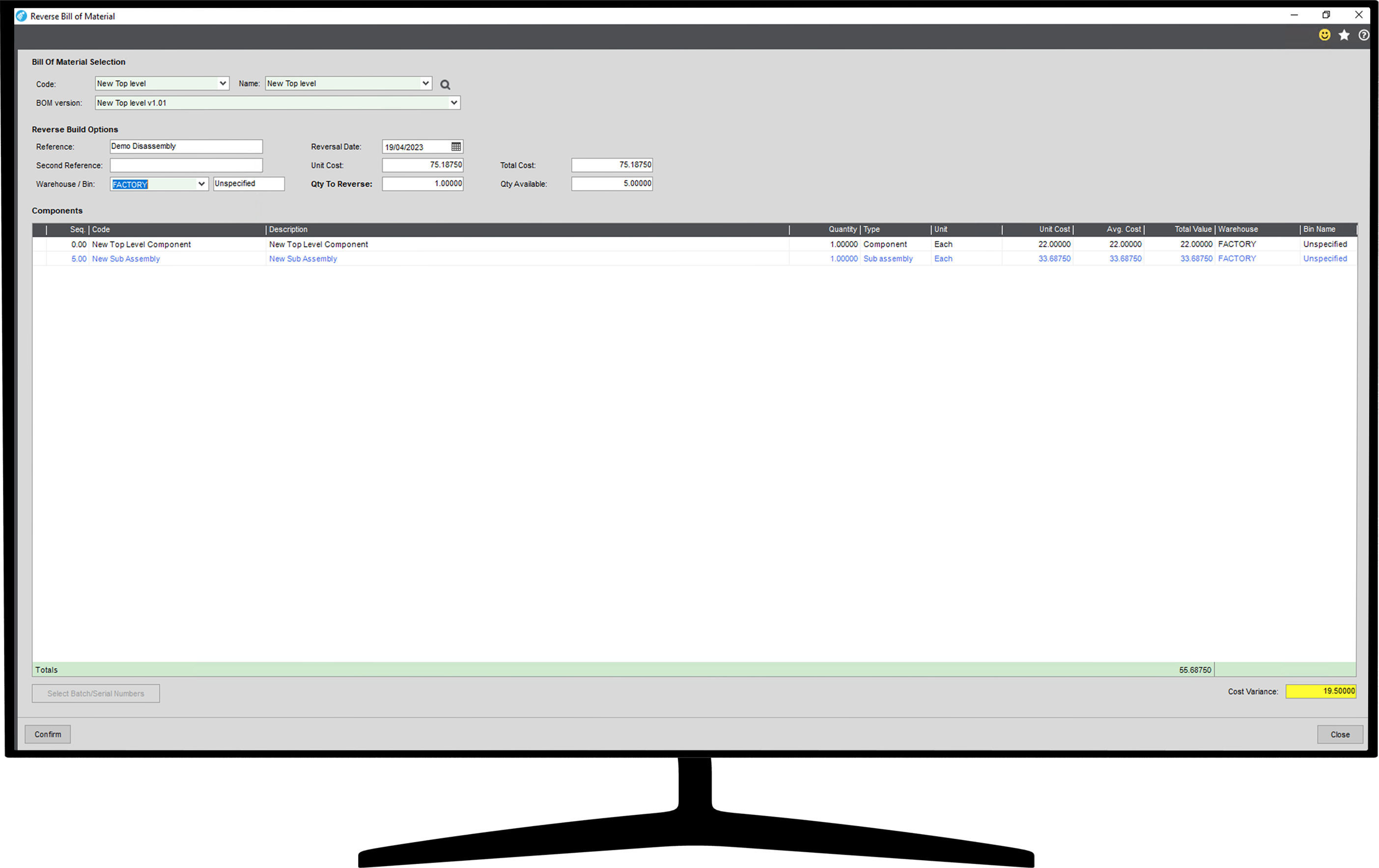

Adhoc Reverse Build

Ideal for environments where items or kits are regularly disassembled.

Cim200’s ad-hoc reverse BOM build functionality allows you to take a finished item out of stock and put all the components back into stock, at any time and at the click of a button, saving valuable data-entry time.

Handling cost variances and providing flexibility on which component items to place into stock, the ad-hoc reverse BOM build functionality provides you with the speed and flexibility you need when disassembling items.

Base Items

Cim200’s base item functionality allows you to output multiple built items from the same Works Order.

Designed for scenarios where a bulk product is manufactured and then dispensed into smaller containers for sale, the base item functionality cuts down on data-entry overhead and paperwork.

Taking a scenario where you manufactured 1000 litres of paint, and wanted to dispense those 1000 litres into tester pots, 500ml, 1litre and 5litre pots, you would need 5 works orders and 5 sets of paperwork in traditional manufacturing systems. With Cim200, the same can be achieved in a single works order record, with a single set of paperwork.

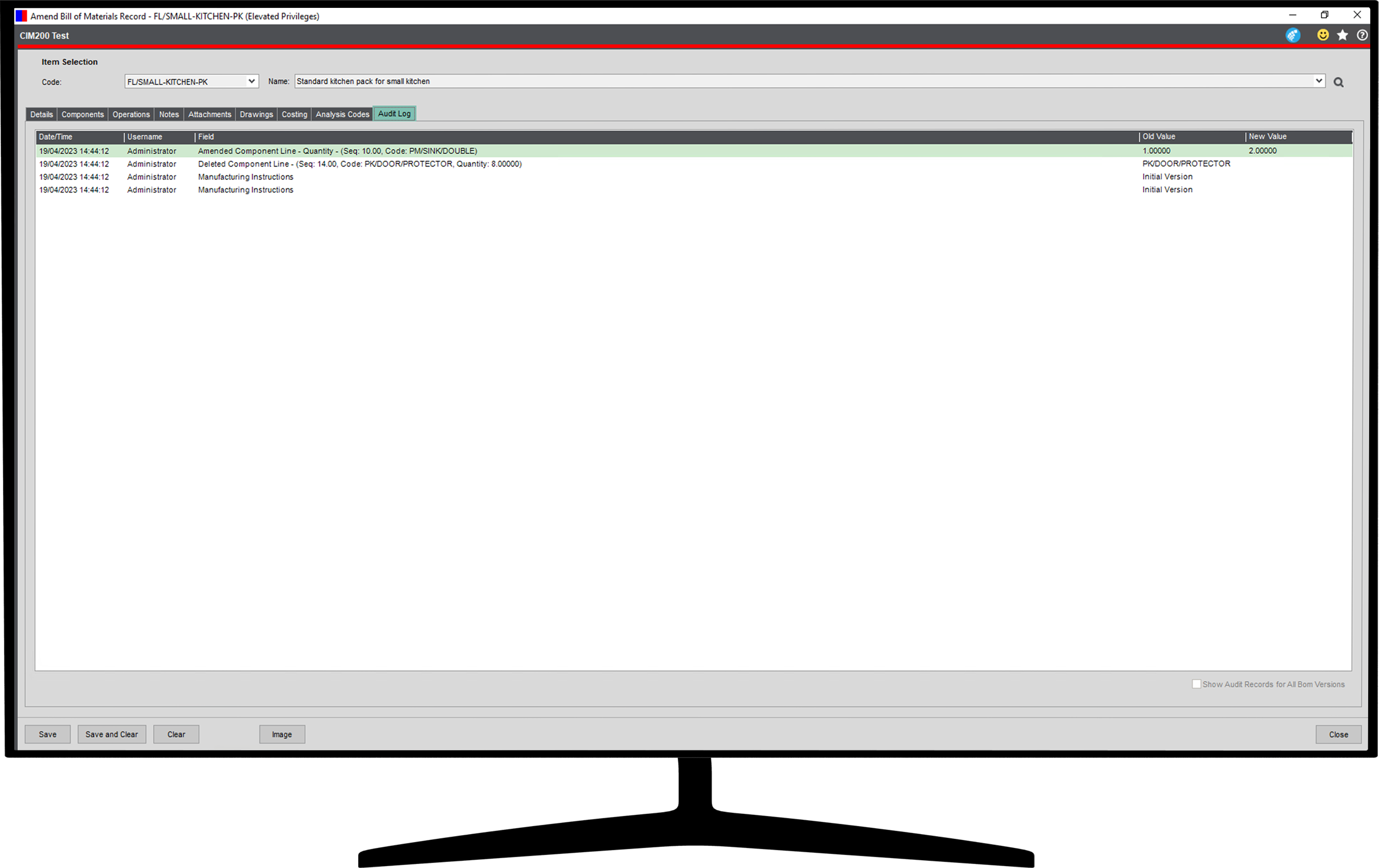

Audit Log

Cim200’s Audit Log functionality extends to Bill of Materials. Capturing and logging any changes, additions or removals on the bill of material and providing you with a comprehensive history of the Sage 200 Bill of Materials, independent of whether version control is enabled or not.

Additional Bill of Materials Features

Features | Description |

|---|---|

Stock Profile | Access the Stock Profile directly from Bill of Materials.

The stock profile screen provides you with a complete situational overview of your stock position, incorporating demands, replenishments, and stock status for a specified item. |

Trial Kit Raise Works Orders | Enhancing the standard Sage 200 Trial Kitting functionality, generate Cim200 Works Orders directly from the Trial Kit screen. |

Component Analysis Codes | Cim200 provides you with 20 Analysis codes that can be defined against individual components on your Bill of Materials, providing you with the flexibility needed to capture any information specific to your individual requirements. |

Operation Analysis Codes | Along with 20 analysis codes on components, the same flexibility is available against operations. Define up to 20 analysis codes against operations and record specific information as you require. |

Rich Text Instructions | Highlight key information in your manufacturing instructions. Cim200’s rich text functionality enables you to ensure important information is quickly identifiable for your manufacturing staff, cutting down on mistakes and issues. |

Cim200 Bill of Materials FAQs

Can’t find the answer you’re looking for? Contact Us

A base item is an item which is manufactured in bulk and subsequently stocked under different finished item product codes. A typical example could be where paint is manufactured in bulk and dispensed and stocked in individual tins, or a cake mixture is manufactured in bulk, placed into individual moulds, baked and then stocked individually.

A percentage BOM is identical to a standard BOM, other than you can define your component quantities as a percentage of a single finished item. When a works order is processed for a percentage BOM, the percentages defined on the BOM are converted based on the quantity required on the works order.

A kit BOM is a setup and configured as per any standard bill of material. The difference is how that bill of material is processed. Standard BOMs are manufactured typically manufactured via Works Orders, whereas Kit BOMs are assembled whilst allocating goods to a sales order, enabling you to quickly and efficiently assemble kits of items together, without the unnecessary overhead of processing a works order.

There is no limit to the number of BOM routes you can define.

There are 20 analysis codes available on the Bill of Material record, along with a further 20 available for each component, and another 20 for each operation.

The audit log captures any changes to static data fields on the Bill of Material, its components and operations, along with the addition or removal of any components or operations.

Cim50 can print labels to any label printer, or onto A4 label sheets as required.