Cim200 - Planning

Utilising Just In Time Planning to Boost Cashflow, Minimise Stock Holding and Meet Deadlines

Manufacturing Planning Software for Sage 200

The Cim200 Planning module is fully integrated with Sage 200 Professional, utilising advanced algorithms and just in time methodology to ensure you meet your customer demands.

The Cim200 Planning Module add the following functionality to Sage 200 Professional:

Ensure Demands are Fulfilled from Across Sage 200 & Cim200

Reading from sales orders, sales forecasts, make to stock, works orders and reorder levels, Cim200 Planning establishes if demands can be met.

Tracking of Shortages and Replenishments

Determine purchase and manufacturing recommendations based on demand versus current stock availability and outstanding replenishments.

Optimise Cashflow with Rule Based Recommendations

Set pre-requisites against stock items, such as reorder rules and lead-times, to only buy and make what you need and when it’s required.

Cim200 Planning & Sage 200

Meeting your customer demand in the timeliest and most cost-effective way is one of the key elements required from your manufacturing software. The Cim200 Planning module is one of the most important in helping achieving this goal. It reads demands from across all modules, whether it be customer demand via a sales order, shopfloor demand from a works order, maintaining stock levels through make to stock, or even demand from a sales forecast in the future. It encapsulates all requirements into one easily controlled screen, detailing all the finished goods and components that are needed to fulfil the demand, giving the user full flexibility to choose the most appropriate supplier or amend the build purchase quantities to suit. The Cim200 Planning module will help you to ensure all replenishments required to satisfy your customer requirements are met.

Included In Our Cim200 Manufacturing Planning Software

-

Demand Schedule

- MRP

- Sales Forecasts

- Make to Stock

- Rescheduling

- Automation

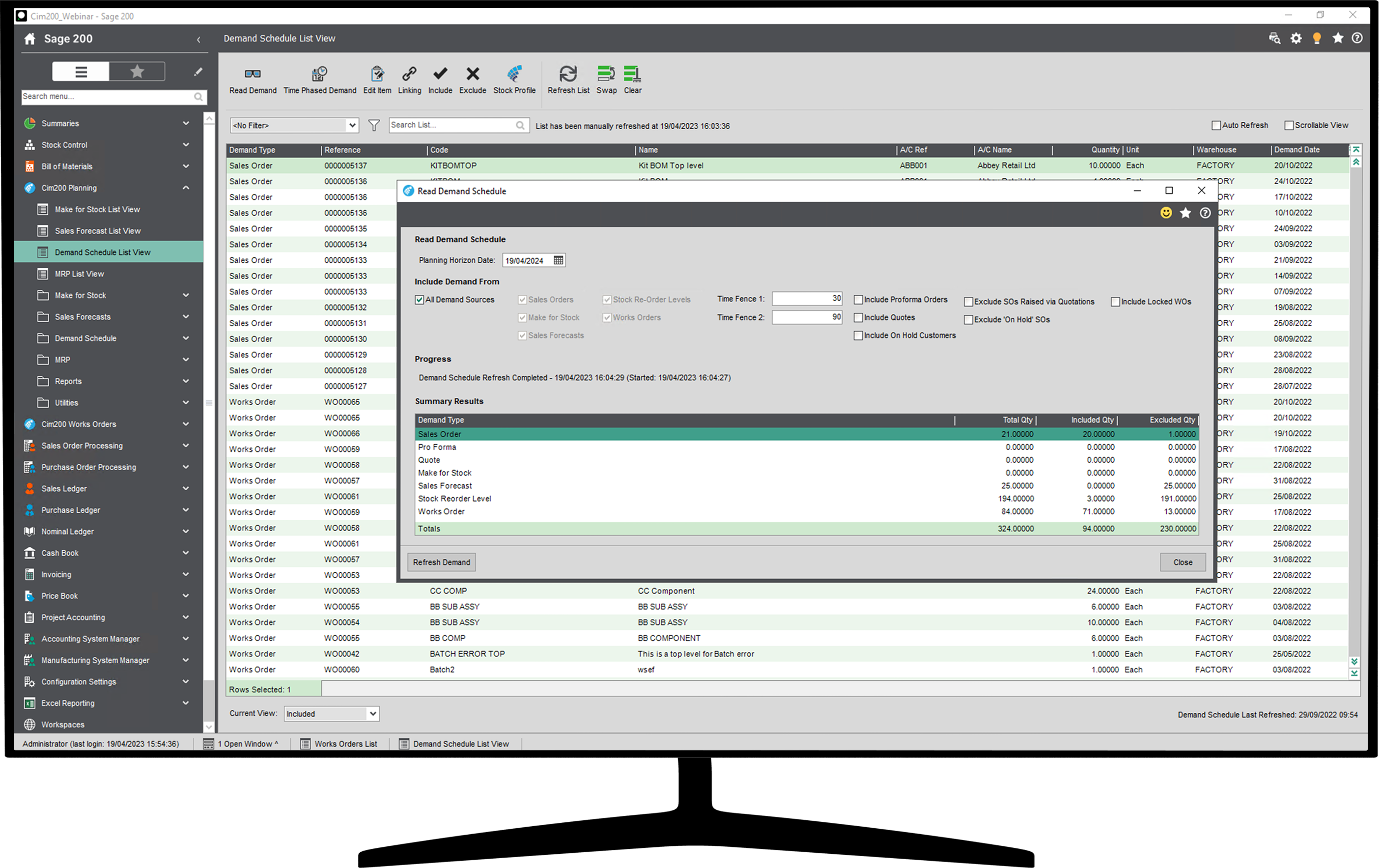

Demand Schedule

Ensuring all demands are taken into account during the Cim200 planning process, the demand schedule provides a list of the demands within the parameters set at the time the schedule was run. It is an ‘explanation’ of what will be considered by MRP, detailing the order references, quantities and dates required.

There is also an ‘exclusion’ list that shows the demand that will not be considered during the next MRP run with a reason for full visibility.

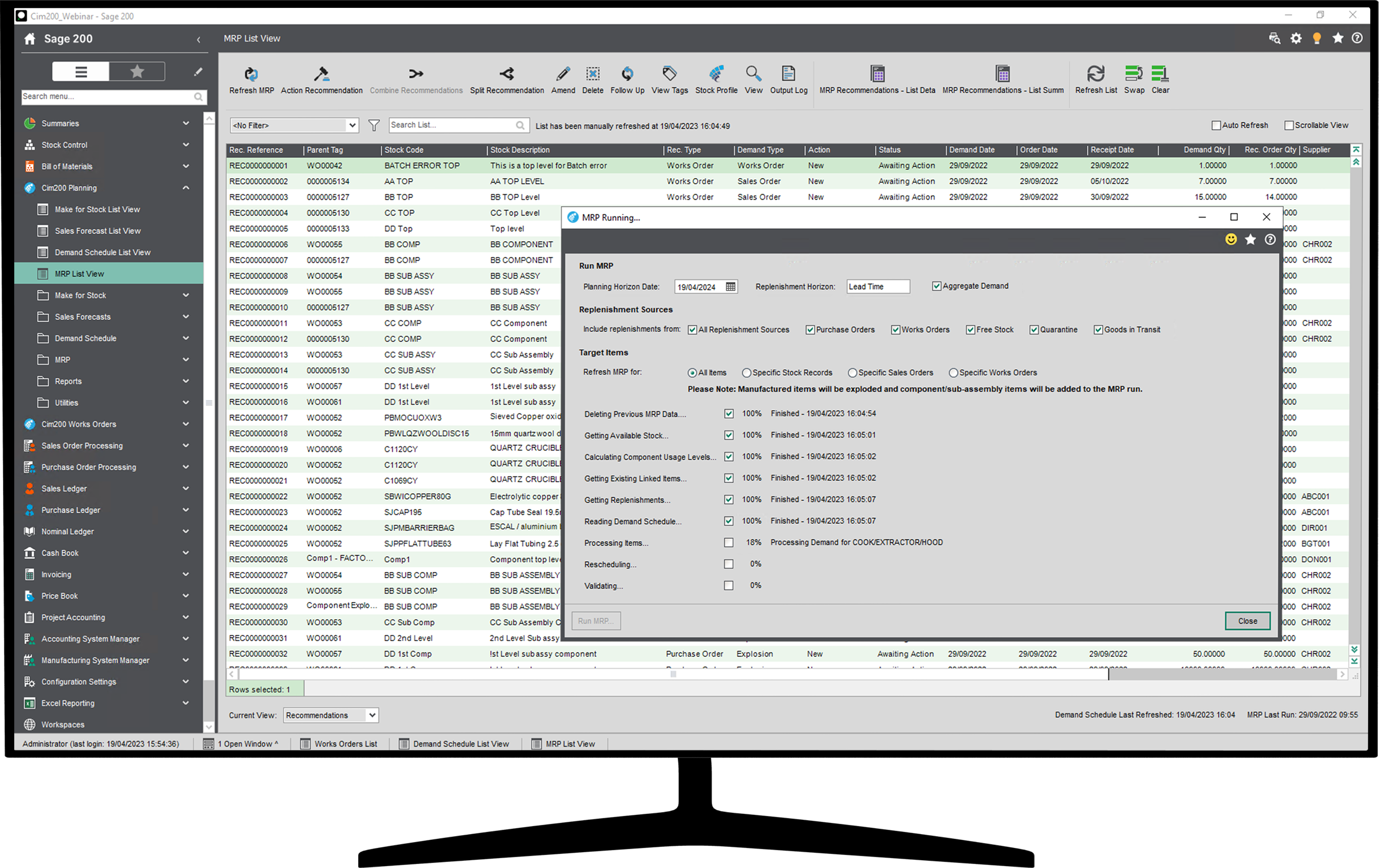

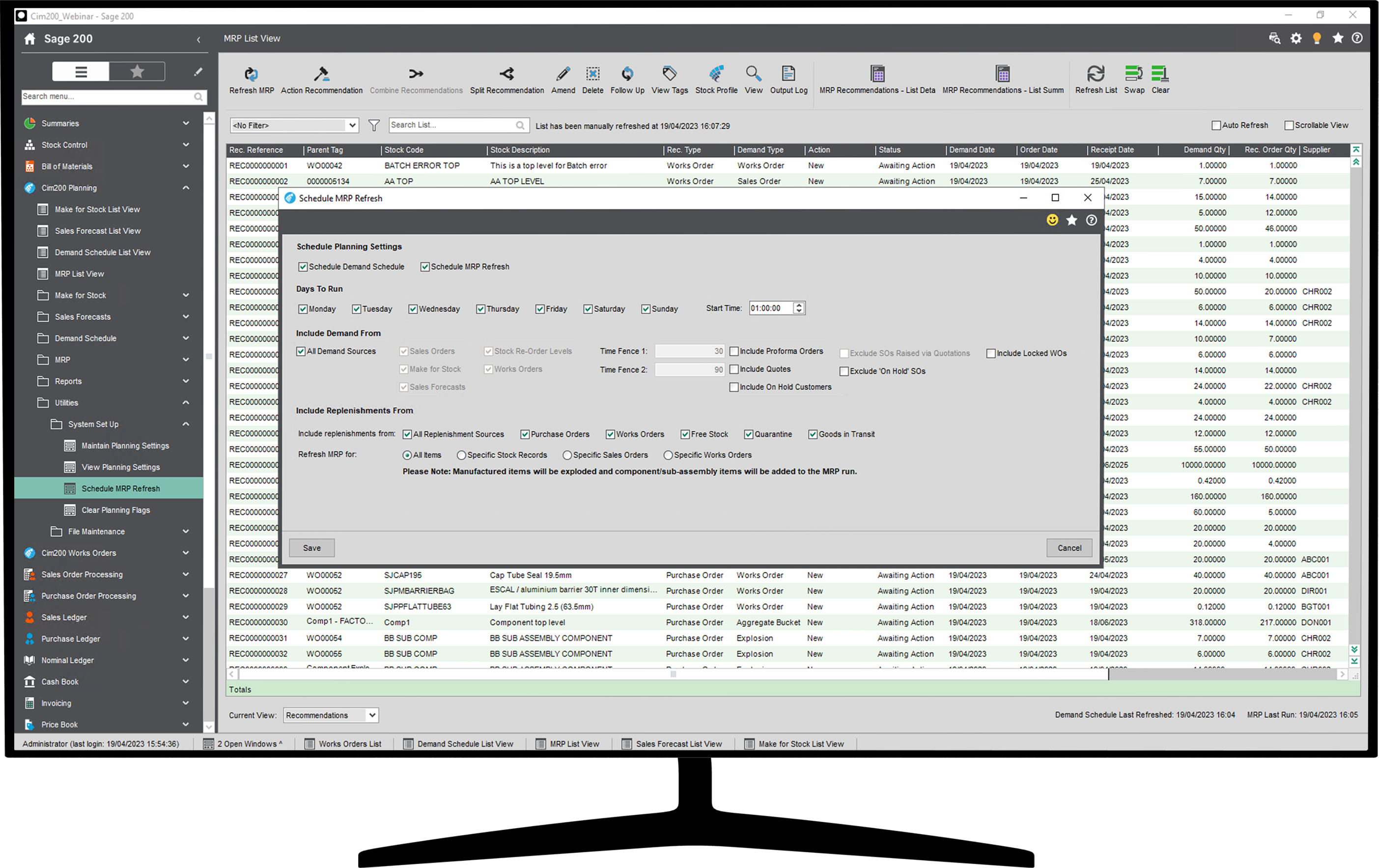

MRP

MRP reads through all the demand generated from the demand schedule and generates a list of recommendations to purchase and manufacture goods to satisfy that demand by the due dates required.

Once MRP is run, you are provided with a list of all the recommended orders, with the tools to interrogate them and action as purchase orders and works orders accordingly.

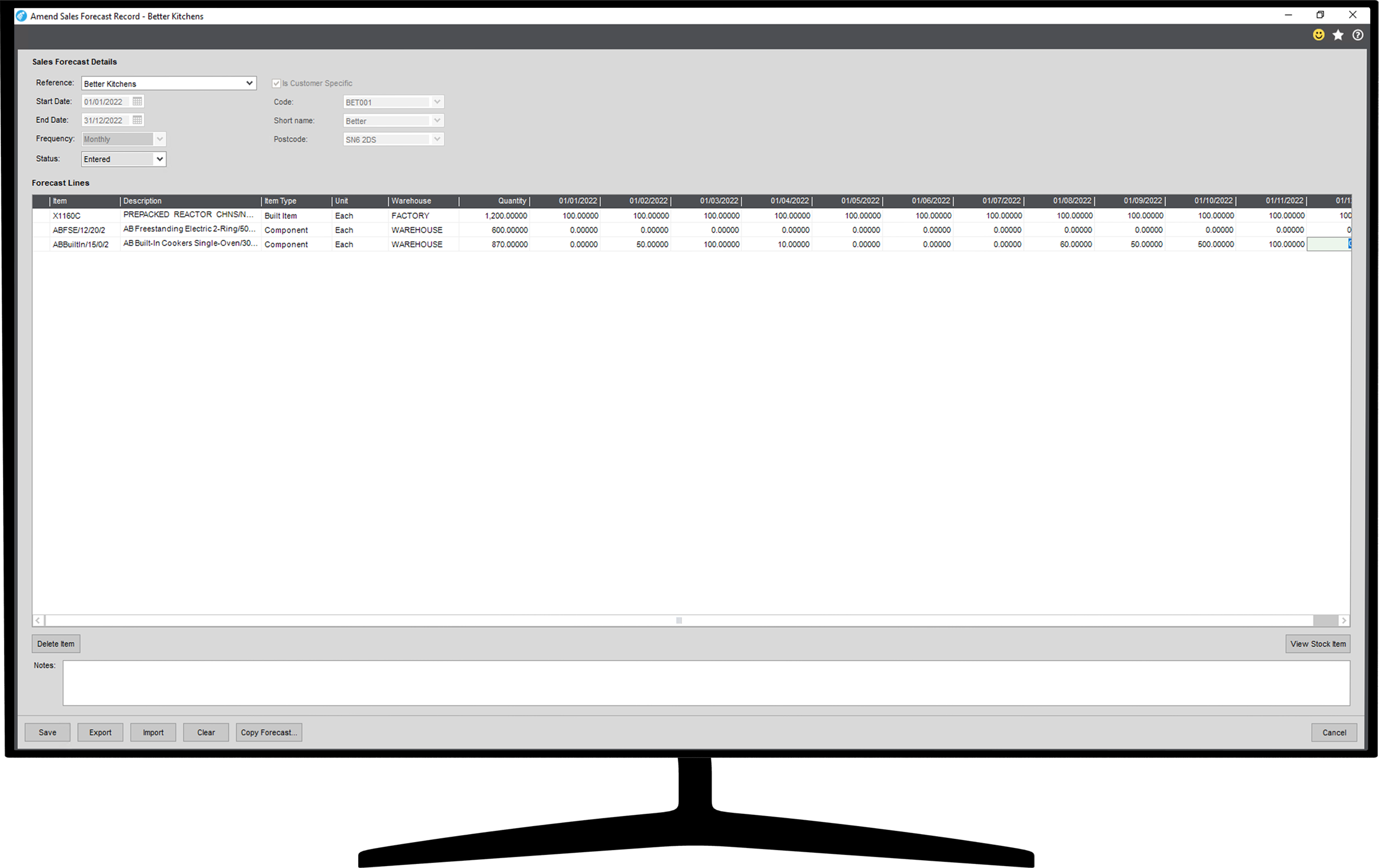

Sales Forecasts

Where customers regularly order products over a set period, but the lead time of the goods supplied is greater than the date span from order to the requirement date, utilise the Cim200 sales forecast functionality.

Sales Forecasts allow demands for customers to be considered prior to them placing the order. Cim200 Planning will use the specified settings to determine whether it creates the demand from the sales forecast or the sales order.

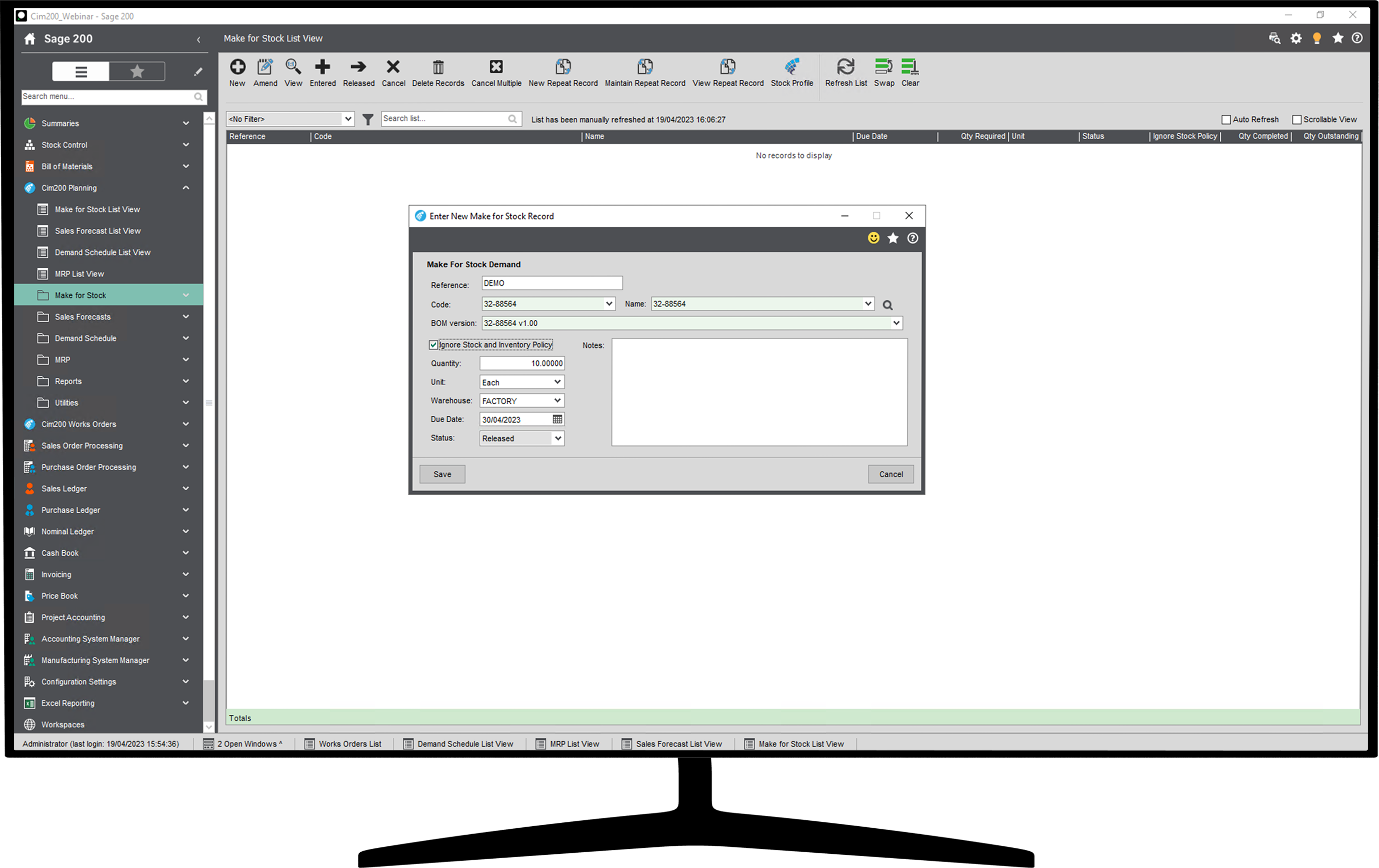

Make to Stock

Although nothing is guaranteed, sometimes you know that you will need a certain amount of stock at a specific time of the year, whether this is due to seasonal demands, or customer promises.

Make for stock allows you to enter your own demand on the system at the dates you request, regardless of any other demands placed within Cim200.

This helps make sure that you have the stock available to supply those customers when you could be at your busiest.

Rescheduling

Once the MRP process has completed its calculations, it will interrogate all existing replenishments on the system to determine if the date they are due to be received is still relevant, or if they are still needed at all.

If the replenishment is still required but the due date on the demand it is needed for has changed, to allow them to be receipted just-in-time for the updated demand due date, MRP will recommend rescheduling the purchase or works orders, avoiding stock being sat on a shelf for any longer than is needed and improving cashflow.

Automation

To save time during office hours, Cim200’s Demand Schedule Refresh and MRP can be scheduled to run out of hours as and when needed.

Additional Planning Features

Features | Description |

|---|---|

Aggregating Demand | Configure each stock item with individual aggregation settings, with options to aggregate by a specific number of days, by calendar week or calendar month. To streamline MRP recommendations and ordering/production processes, all demand that falls within the aggregate demand buckets will be combined automatically. |

Firm Planning | To ensure that the Planning system does not recommend altering production plans within a specified timeframe, employ Firm Planning Periods. |

Tags and Links | Via the simple yet powerful tagging system, easily track and identify what replenishments will be used to satisfy which demands. Quickly and easily convert a planning Tag to a firm link to ensure the planning system does not re-tag a replenishment that you wish to use for a specific demand. |

Stock Profile | Access the Stock Profile directly from MRP. The stock profile screen provides users with a complete overview of the stock position of a specified stock item, incorporating demands, replenishments, and stock status. |

Safety Lead Times | To ensure you can meet your customer expectations regardless of any potential delays, define individual purchase or production safety lead times. |

Jobbing | To allow the of production of products to meet customers specific requirements, jobbing production method is employed. With Cim200, it is possible to specify which stock records should be processed in this way, giving you flexibility to produce certain items to order, rather than a batch manufacturing process. |

Cim200 Planning FAQs

Can’t find the answer you’re looking for? Contact Us

Yes, Cim200’s Demand Schedule Refresh and MRP run can be scheduled to run at any time.

Once the MRP system has generated a list of recommendations, it is possible to raise works orders directly into the Cim200 works order module from the recommendations lists.

Using the enquiries available in Cim50, you can easily see any movement related to a batch or serial number, from being receipted in to stock, to usage on a works order or being despatched to a customer.

Once the MRP system has generated a list of recommendations, it is possible to raise purchase orders directly into the Sage 200 purchase order module from the recommendations lists.

To allow just in time planning, MRP considers lead times of components and materials setup against each stock item and suppliers within the Sage 200 Stock Control module, with the default coming from the preferred supplier.

For ease of use, sales forecasts can be imported into Cim200 from a spreadsheet that may have been provided by a customer or based on calculated values.

Make to stock (MTS) is a production approach in which companies manufacture products based on anticipated demand and stock for immediate sale. This strategy is often used for items with stable demand patterns and long production lead times.

Just In Time (JIT) planning is a production strategy that aims to produce manufactured items exactly when they are needed, without unnecessary stock holdings. JIT planning involves coordinating every stage of the production process to ensure that materials and resources are available precisely when they are required. This approach helps companies to reduce costs, increase efficiency, and improve quality.

Material Requirements Planning (MRP) is a method that helps manufacturing businesses to plan and control the flow of materials needed for production. MRP software calculates the quantity and timing of raw materials, components, and subassemblies needed to fulfil demands, considering factors such as lead time, order rules and stock levels. This allows businesses to optimise their stock levels, minimise shortages and excess stock, and improve production efficiency.