Cim200 - Works Orders

Control Production, Work in Progress and Capacity of Resources Accurately

Works Orders Software for Sage 200

The Cim200 Works Order module is fully integrated with Sage 200 Professional, allowing the control of built items through each stage of the manufacturing process.

The Cim200 Works Orders Module adds the following functionality to Sage 200 Professional:

Track Production Throughout Each Stage of Manufacturing

Evaluate rough cut resource availability and produce shop floor documentation with comprehensive instructions and timings.

Analyse Actual vs Estimated Costs of Production

Ensure reliable works order costings that remain within budget by monitoring material, machine, tooling, subcontract and overhead costs.

Maintain Material Allocations and Work in Progress

Allocate and issue components to production orders and control sub-assemblies, to enable accurate stock holdings and comprehensive WIP analysis.

Cim200 Works Orders & Sage 200

Setting up your stock items and bill of materials is just half the battle when trying to maintain the items you are manufacturing and selling. The Cim200 Works Order module gives you the functionality to control and monitor all items that are currently being manufactured, either as sub-assemblies for other bill of materials, or as finished items to be despatched on sales orders to fulfil your customer demand. A suite of powerful enquiry screens and documents provides your production staff with complete visibility to track each process effortlessly. Production managers can utilise Cim200 capacity planning functionality to ensure there is sufficient capacity to satisfy your demand.

Included In Our Cim200 Works Orders Module

-

Trial Kitting

- Capacity Planning

- One to Many Works Orders

- Costing

- Subcontract

- Quality

- Work To List

- Percentage Works Orders

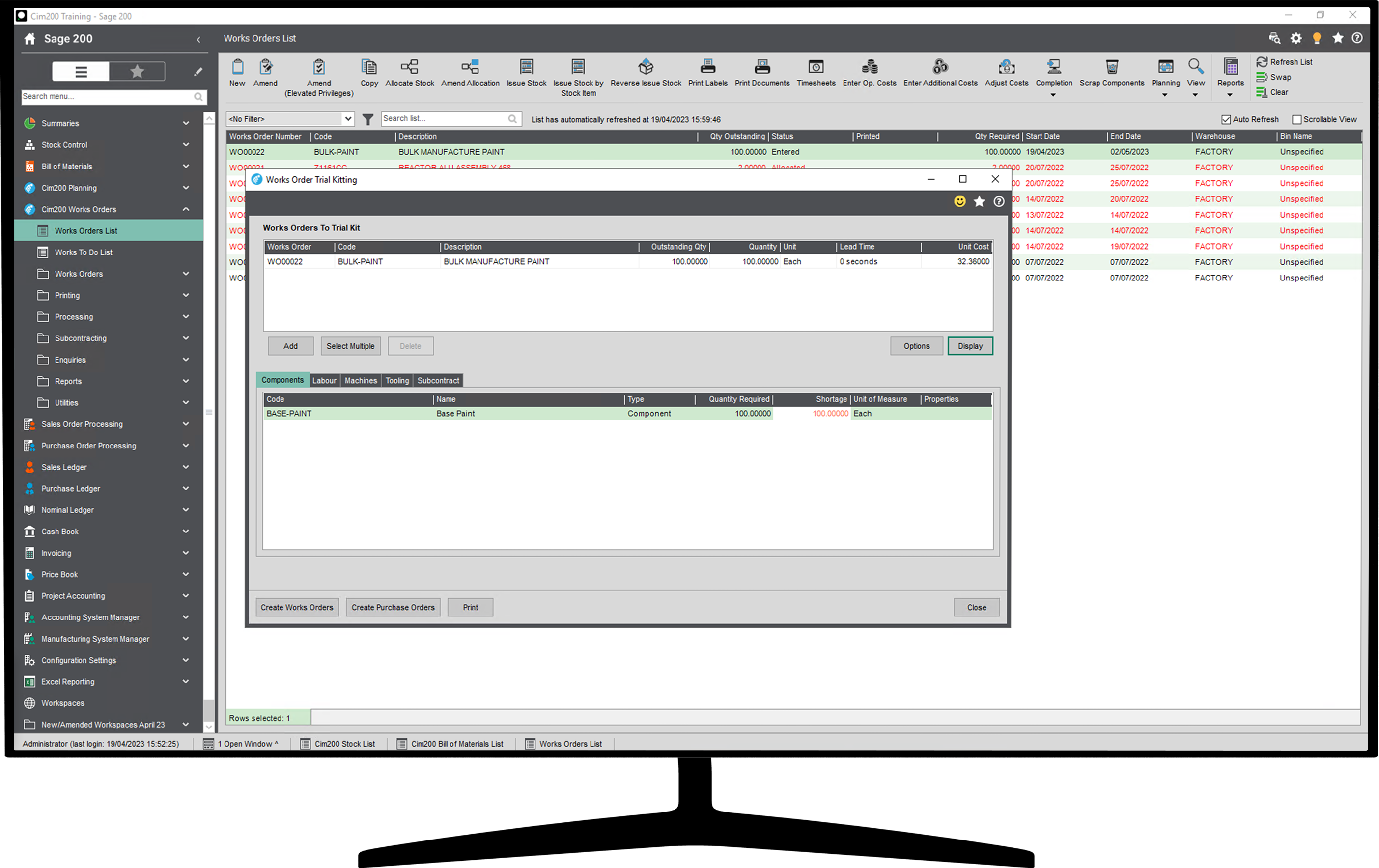

Trial Kitting

Utilise trial kitting to ensure your component stock levels are sufficient to fulfil specific works order demand.

View a list of shortages for multiple works orders and raise replenishment orders from within one easy to use screen.

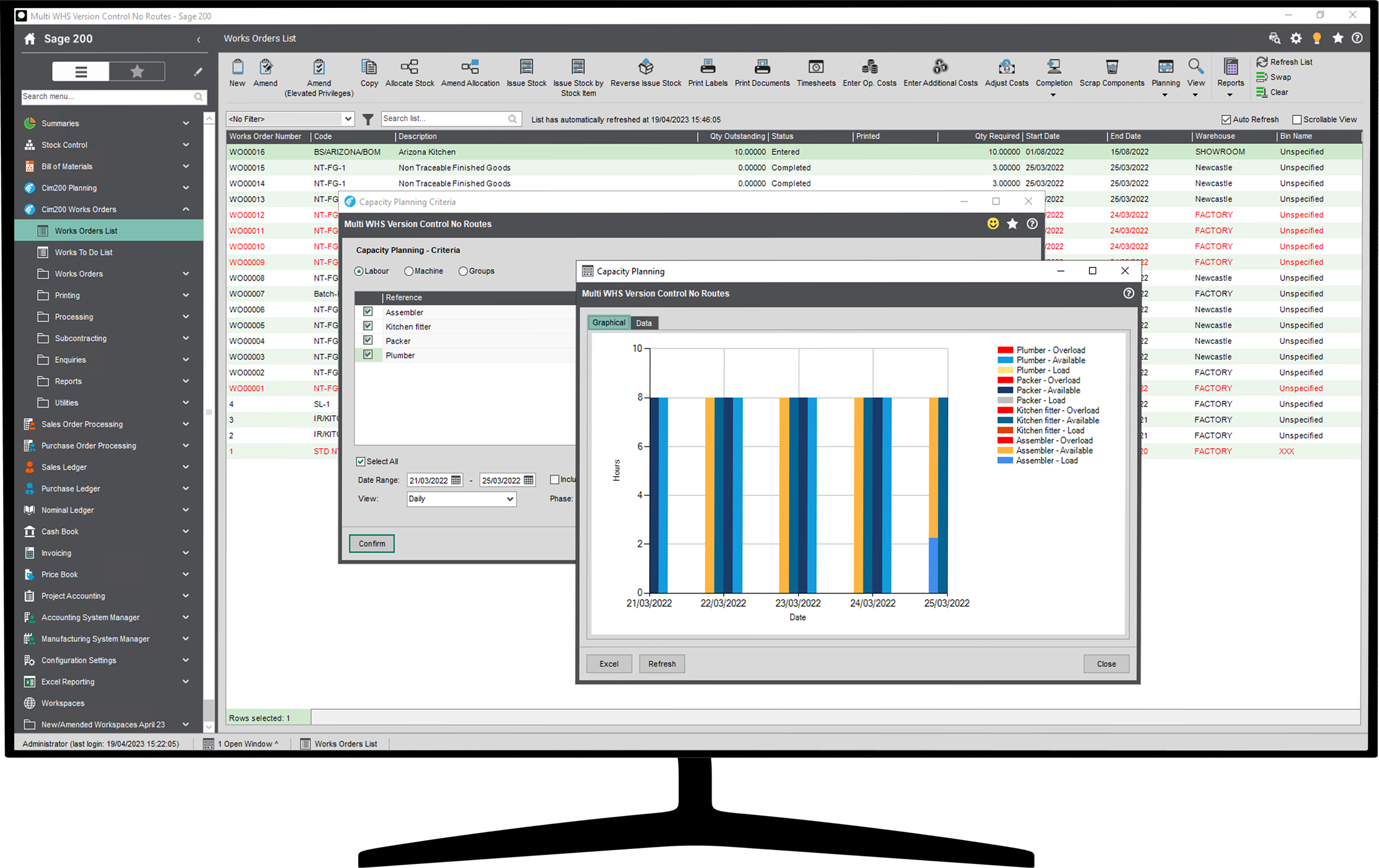

Capacity Planning

The Cim200 rough-cut capacity planning functionality provides a complete overview on the load and capacity across all resources for any given period of time.

Specify which resource group you would like to interrogate, along with the start date and whether you want to view daily, weekly, or monthly demand.

Move resource capacity on the fly to see what impact it has on your production loading, allowing you to plan overtime or reschedule jobs accordingly.

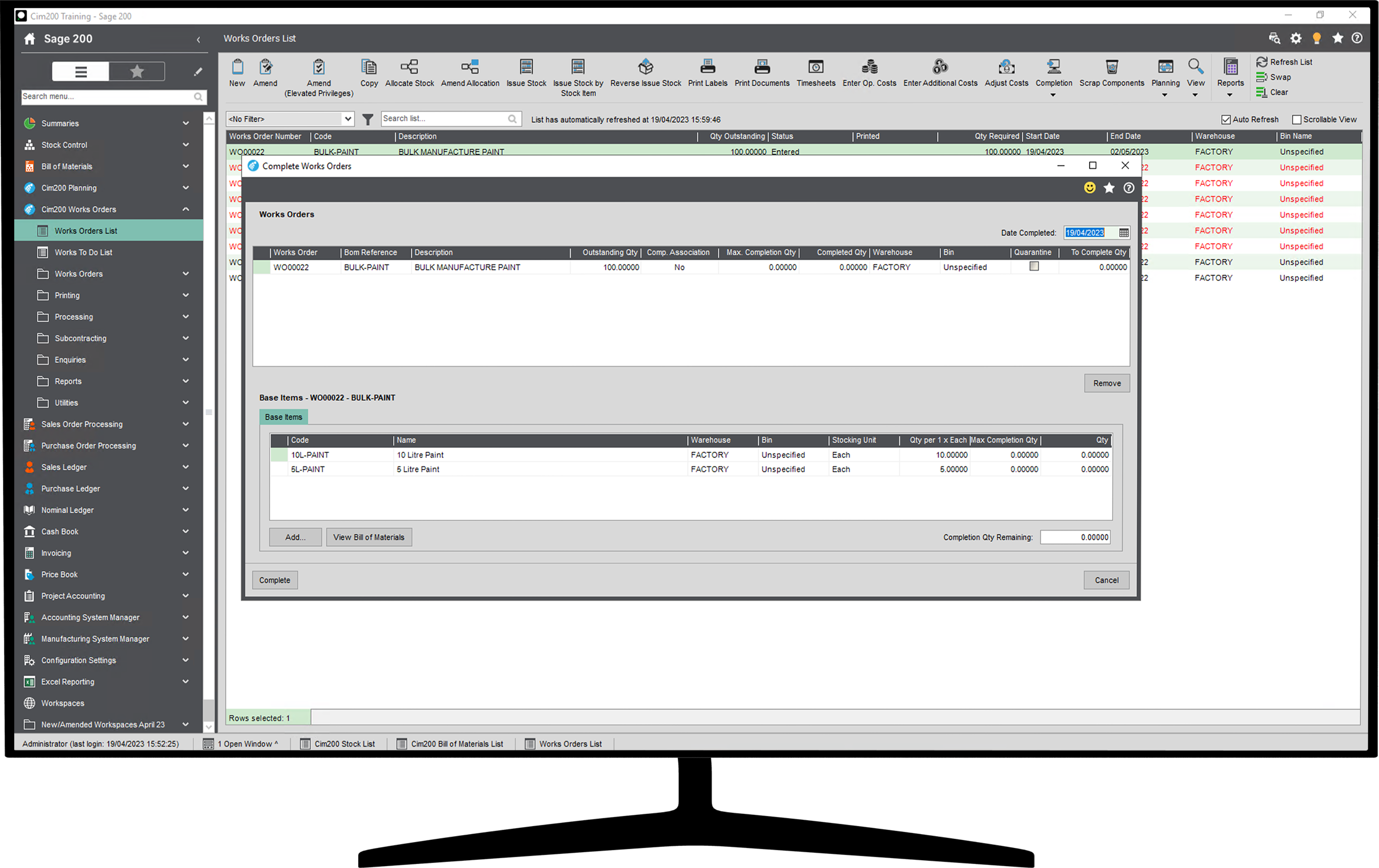

One to Many Works Orders

Employing the Cim200’s base item functionality, when completing works orders, users will be given a list of possible outputs with a conversion to the works order quantity.

Designed for businesses that deal with bulk products that are manufactured and then stocked in smaller containers, the base item functionality reduces paperwork and data entry.

Taking a scenario where you manufactured 1000 litres of paint, and there is a requirement to dispense the 1000 litres into tester pots, 500ml, 1litre and 5litre pots, generally 5 works orders and 5 sets of paperwork would be needed in traditional manufacturing systems.

To reduce overheads, with Cim200 Manufacturing the same can be achieved using a single works order record, with one set of paperwork.

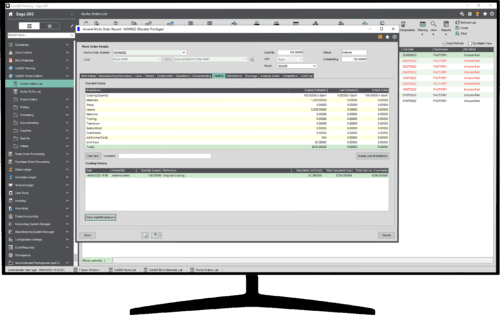

Costing

For analysis and profitability of jobs, compare estimated costs when the works order was raised, along with the latest estimate, and the actual once the job is completed, fully broken down by material, labour, machine, setup, teardown, tooling, subcontract, additional expenses, and overheads.

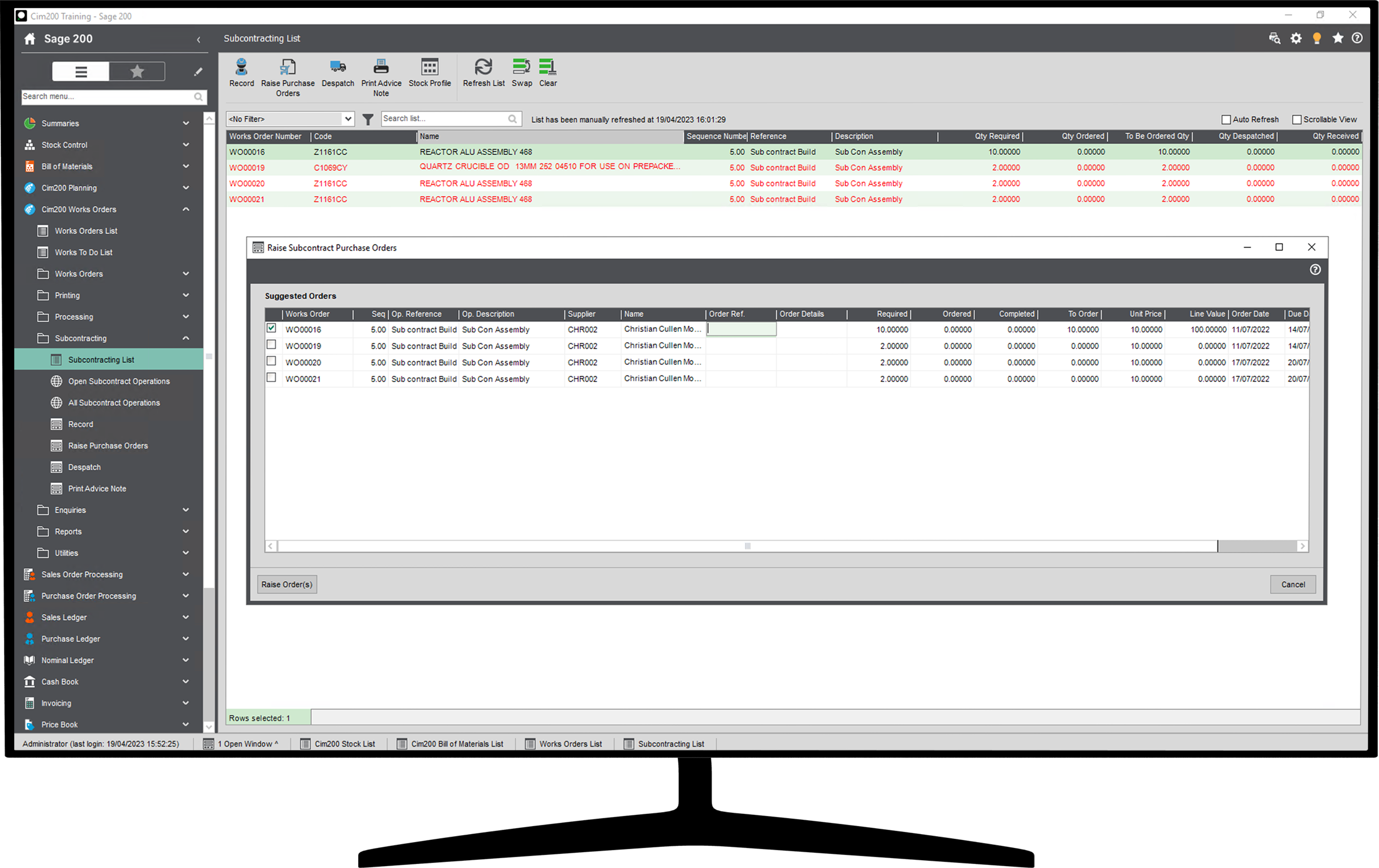

Subcontract

To ensure complete control of external processes, deploy the subcontract feature to raise the required subcontract purchase orders, along with despatching the components and receiving them back in to work in progress once the subcontract process has been carried out.

Subcontracting shows you any items that are currently ‘out’ at the supplier and the dates required, along with the quantities.

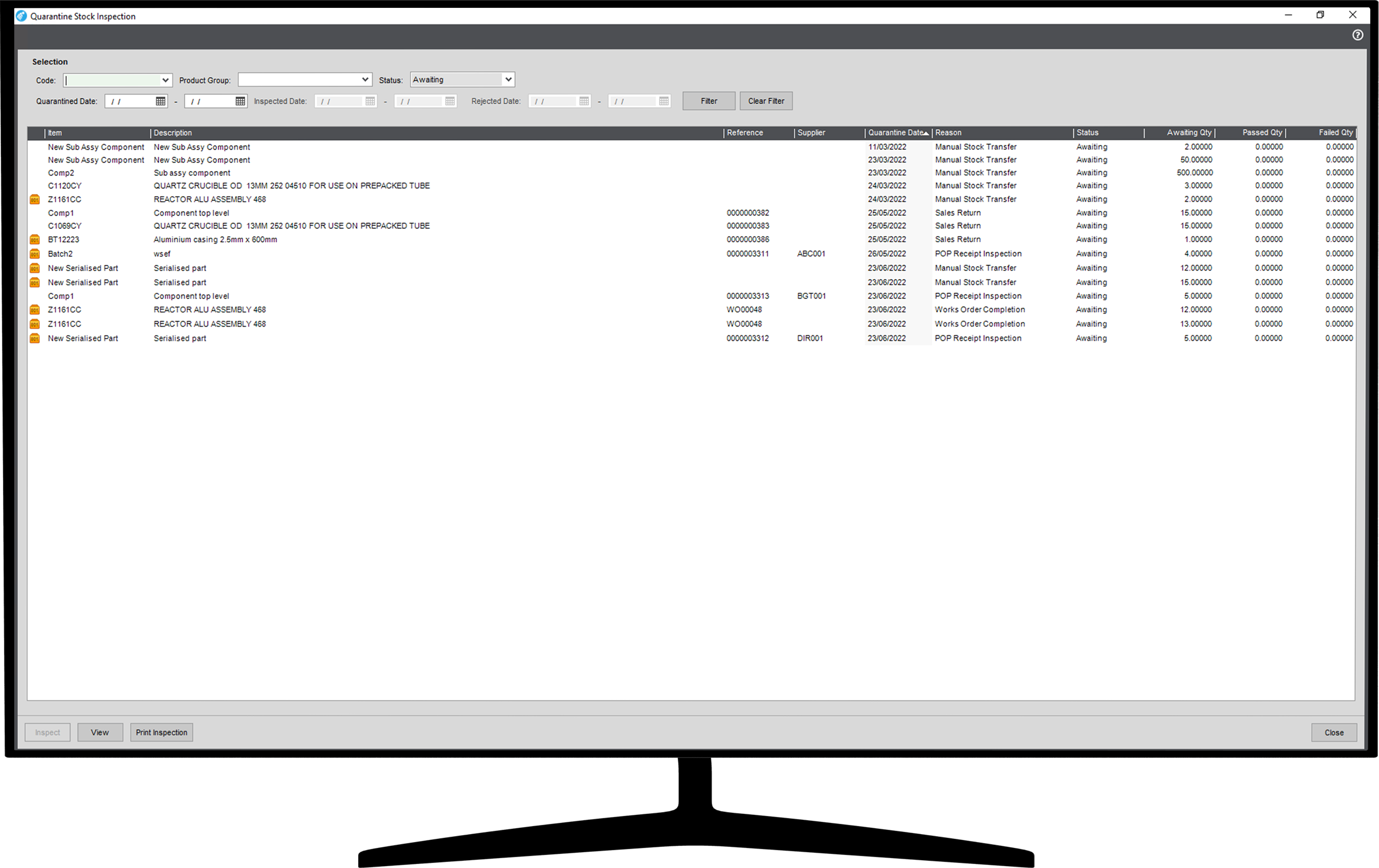

Quality

In certain industries it is inevitable that components, or even the finished goods themselves, will be scrapped due to a fault during manufacture.

Cim200 allows you to scrap these items, recording the reason why, by whom, and when.

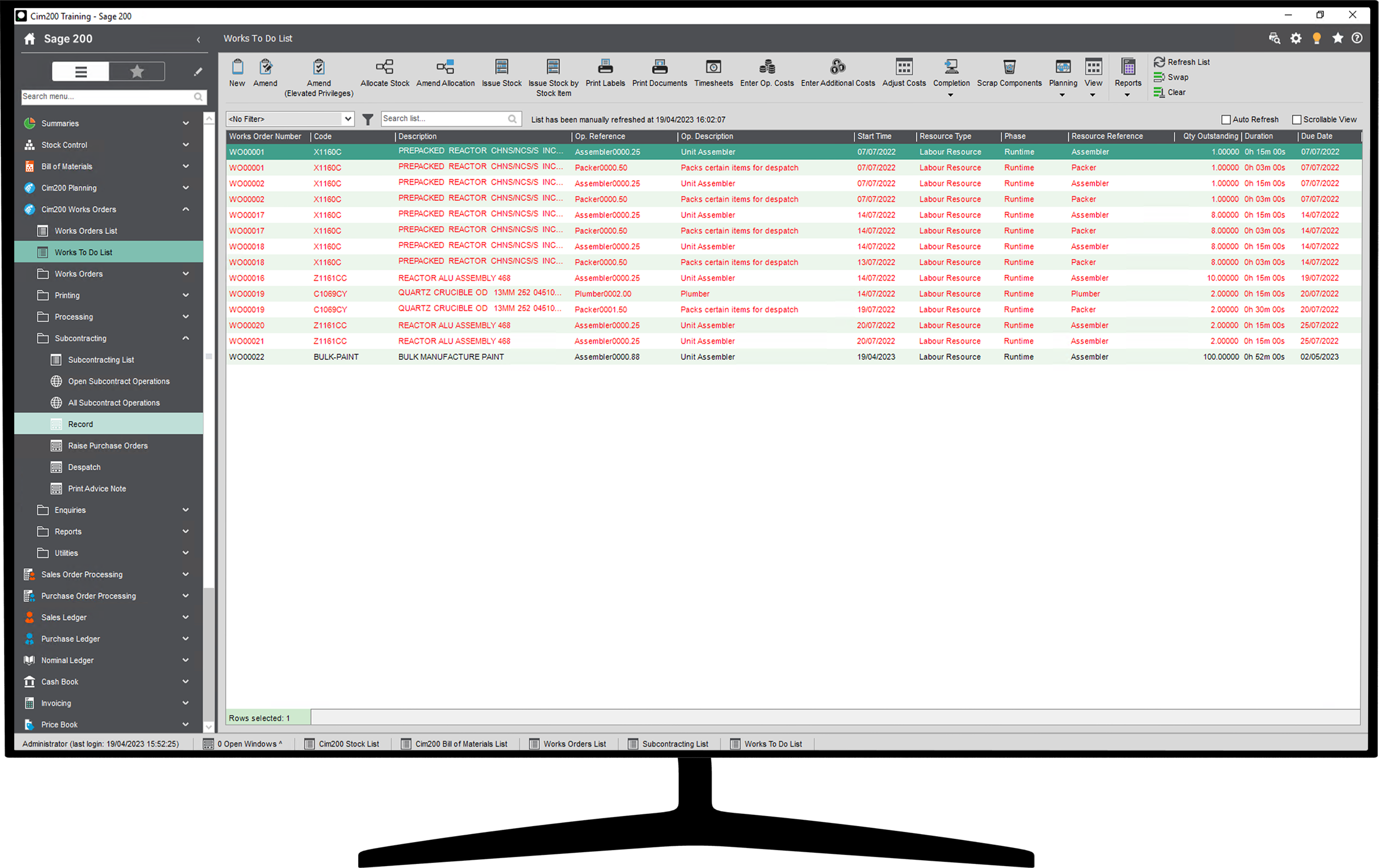

Work To List

For greater visibility across production, employ an additional list view showing every outstanding works order operation, detailing the operation start date, setup time and run time.

The Work To List is live and does away with the need to run traditional work to reports that become out of date very quickly.

Filter the Work To List by labour or machine resource for individual work centre views.

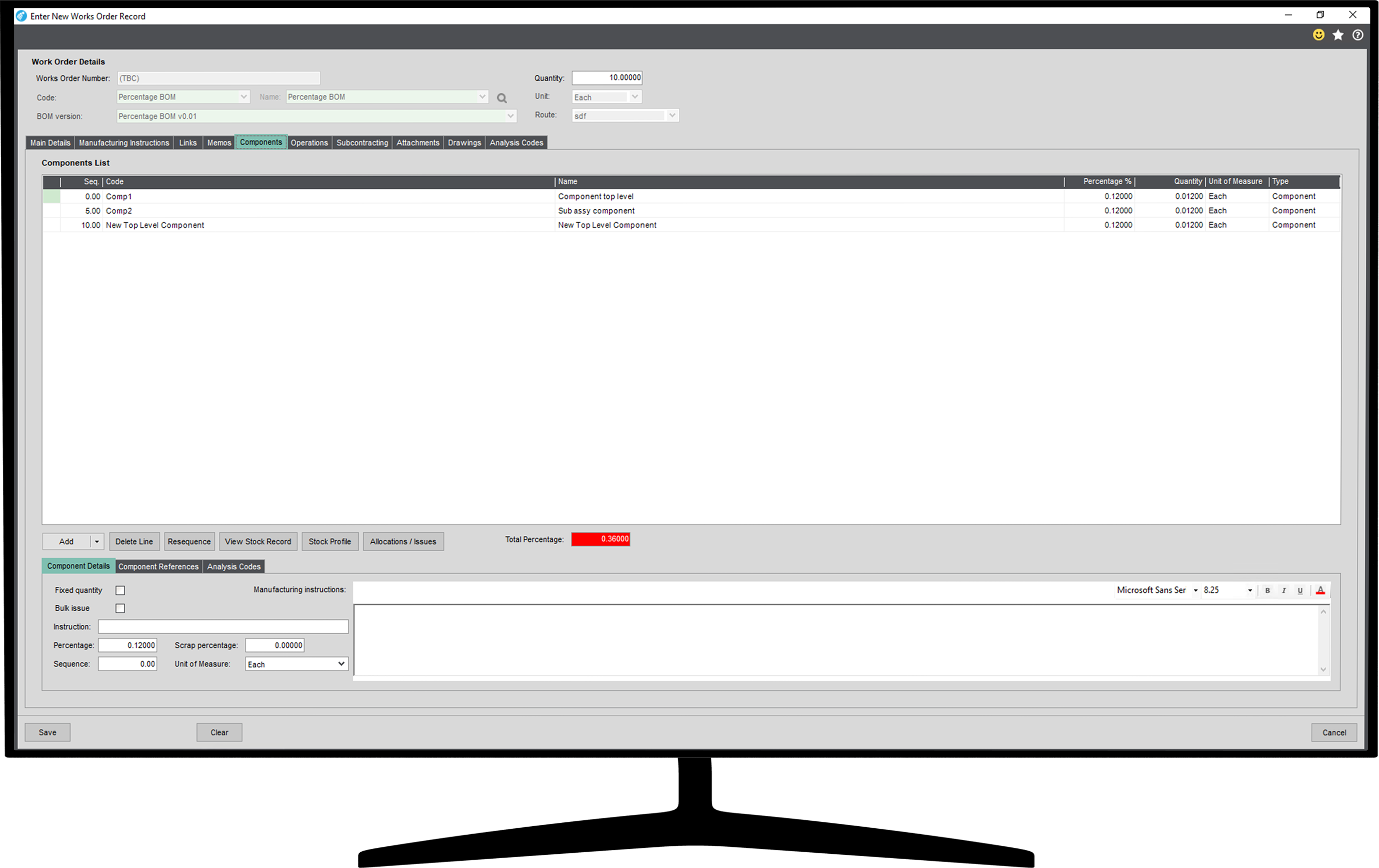

Percentage Works Orders

Specifically designed for liquid/chemical and food manufacturers, have the manufacturing solution work the way you do.

Building on Cim200’s percentage Bill of Materials functionality, allowing the configuration of Bill of Material components as a percentage on the finished product, these percentages are converted to the relative quantity for ease of allocation and issue to works orders.

Additional Works Orders Features

Features | Description |

|---|---|

Reverse Completion | Providing flexibility around the completions of works orders, the Reverse Completion functionality allows for a works order completion to be reversed, removing the completed quantity from stock and placing component items back into WIP. |

Linking | To ensure products are being manufactured to customers’ requirements, works orders can be firm linked to Sales Orders preventing MRP relinking the order. The Sales Order can be viewed directly from the Works Order Links tab whether it is a firm linked order or an MRP linked order. |

Memos | Collaborate across the production process with date/time and user stamped memos against works order records. |

Operation Times | For some companies, default times set on operations are sufficient to cost the job, however, many need more accurate costs.

Using the Cim200 operation times and costs functionality, book times for a specific employee with their own rate, using a designated machine that also has its own cost, for a specified works order. This ensures that every second booked against a job is costed accurately. |

Audit Log | The audit log will track changes made to static fields, components and operations added or removed, how the order was created or cancelled by date/time and user. |

Nominal Integration | Taking advantage of Sage 200 advanced accounting functionality, Cim200 extends the Stock Control to Nominal Ledger integration to works orders, posting component issues to WIP along with operational processing costs. |

Traceability | If traceability is required, it is crucial that the correct batch or serial number is allocated and issued to the job. With traceability in Cim200, easily track where an item has been used, and what batch or serial numbers were produced from a works order. |

Shop Floor Documentation | To produce paperwork for Works Orders, as standard, Cim200 Works Orders comes with a pre-configured Picking List, Route Card, Job Sheet and Operation Card, as well as both “In-Progress” and “Completion” labels.

To meet the specific requirements of a business the documents produced from Cim200 are fully configurable and can be tailored to suit your needs. |

Jobbing | Jobbing production method can be employed to allow the of manufacture of products to meet specific requirements of customers. With Cim200, it is possible to specify the stock item that should be processed using a jobbing method, giving businesses the flexibility to produce certain items to order, rather than using a batch manufacturing process. |

Cim200 Works Orders FAQs

Can’t find the answer you’re looking for? Contact Us

One-to-many works orders enables users to book multiple different items into stock from a single works order. Designed to assist businesses that deal with the manufacture of bulk products that are stocked and sold in smaller containers, this functionality reduces paperwork and data entry.

Taking a scenario where a company manufactures 1000 litres of paint, and there is a requirement to dispense the 1000 litres into tester pots, 500ml, 1litre and 5litre containers, generally 5 works orders and 5 sets of paperwork would be needed in traditional manufacturing systems.

Percentage works orders allow liquid/chemical and food manufacturers to raise works orders with components quantities relative to the finished item quantity.

The percentages are pre-configured on the Bill of Material components as a percentage on the finished product.

Utilise Cim200’s one-off works order functionality, generating a works order for a one-off, non-stocked product to produce one-off/bespoke items.

With the linking functionality provided within Cim200 works orders, it is possible to view which works orders are specifically tagged or linked to a customer, providing full visibility across the manufacturing business.

Labour costs can be recorded directly into Cim200 via either the operational cost entry screen, or via employee time sheets. You can also book time and costs via the Cim200 Shop Floor Data Capture module.

If you do not want to capture actual operational costs, the system will automatically include the expected operational costs into the finished product cost price.

Rough Cut Capacity Planning (RCCP) is a preliminary capacity planning process that helps manufacturers assess whether they have enough resources to meet production demands. It involves estimating overall capacity requirements and identifying any constraints or bottlenecks that may hinder production. It helps manufacturers ensure they have the necessary resources to meet production goals and avoid disruptions.

It is possible to allocate stock to works orders, allowing the reservation of stock before issuing to work in progress, ensuring that the necessary raw materials or components are available when they are needed and helps keep track of free stock levels, thus preventing delays or interruptions in the production process.

To allow the of production of products to meet customers specific requirements, jobbing works orders can be adopted.

Providing flexibility to produce certain items to order, rather than a batch manufacturing process, with Cim200 manufacturing, it is possible to specify the stock records that should be processed in this way.