Cim50 – Bill of Materials

Utilising Multi-Level Bill of Materials with Detailed Costing & Audit Functionality

Bill of Materials Software for Manufacturers

With Cim50’s Bill of Materials module, configure your built items with advanced functionality that fully integrates with Sage 50 Accounts.

Track Ongoing Costing History For All Manufactured Items

Improve profitability by accurately calculating the cost of bill of materials including material, labour and machine overheads with full costing history.

Maintain Bills of Materials With Unlimited Components & Levels

Configure your built items to meet all necessary manufacturing specifications, no matter the complexity or number of components.

Ensure Shortages Are Fulfilled With Trial Kitting & Built Items

Verify there is enough stock to assemble multiple bill of materials, review machine & labour requirements and record built items.

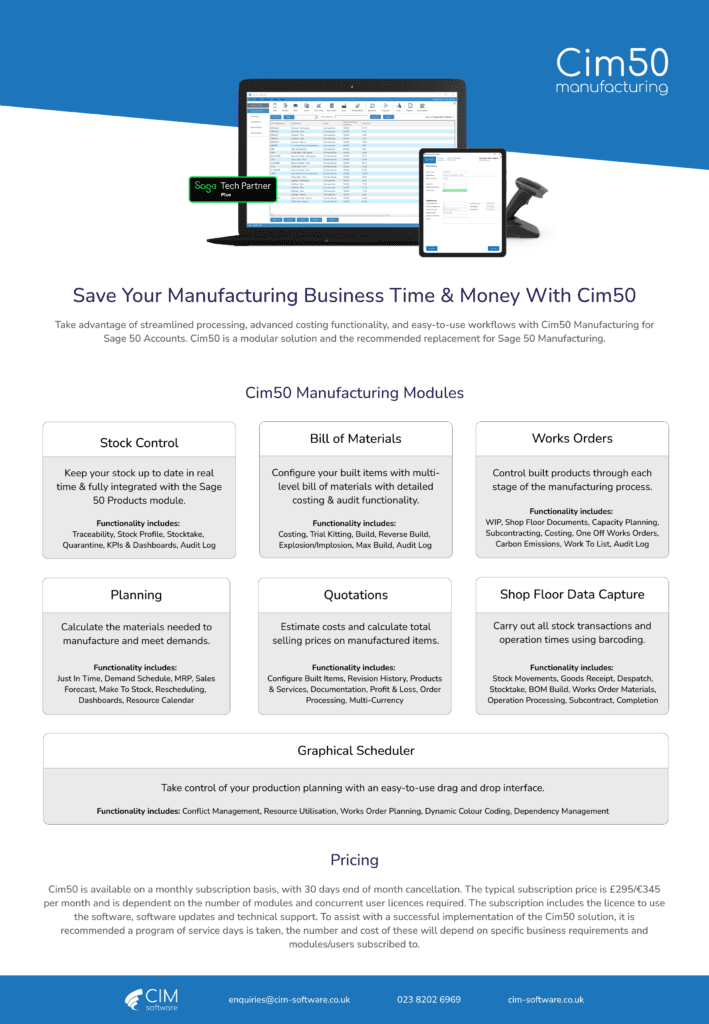

Included In Our Cim50 Bill of Materials Module

-

Costing

- Trial Kitting

- Build

- Reverse Build

- Explosion/Implosion

- Max Build

- Audit Log

Costing

With Cim50 Bill of Materials, take advantage of ongoing costing history, giving you the confidence that your build and purchase costs are accurate. Visualise your exact costing breakdown using the on-screen chart.

Calculate the cost of building your bill of materials, including material, labour, setup, machine and overheads costs.

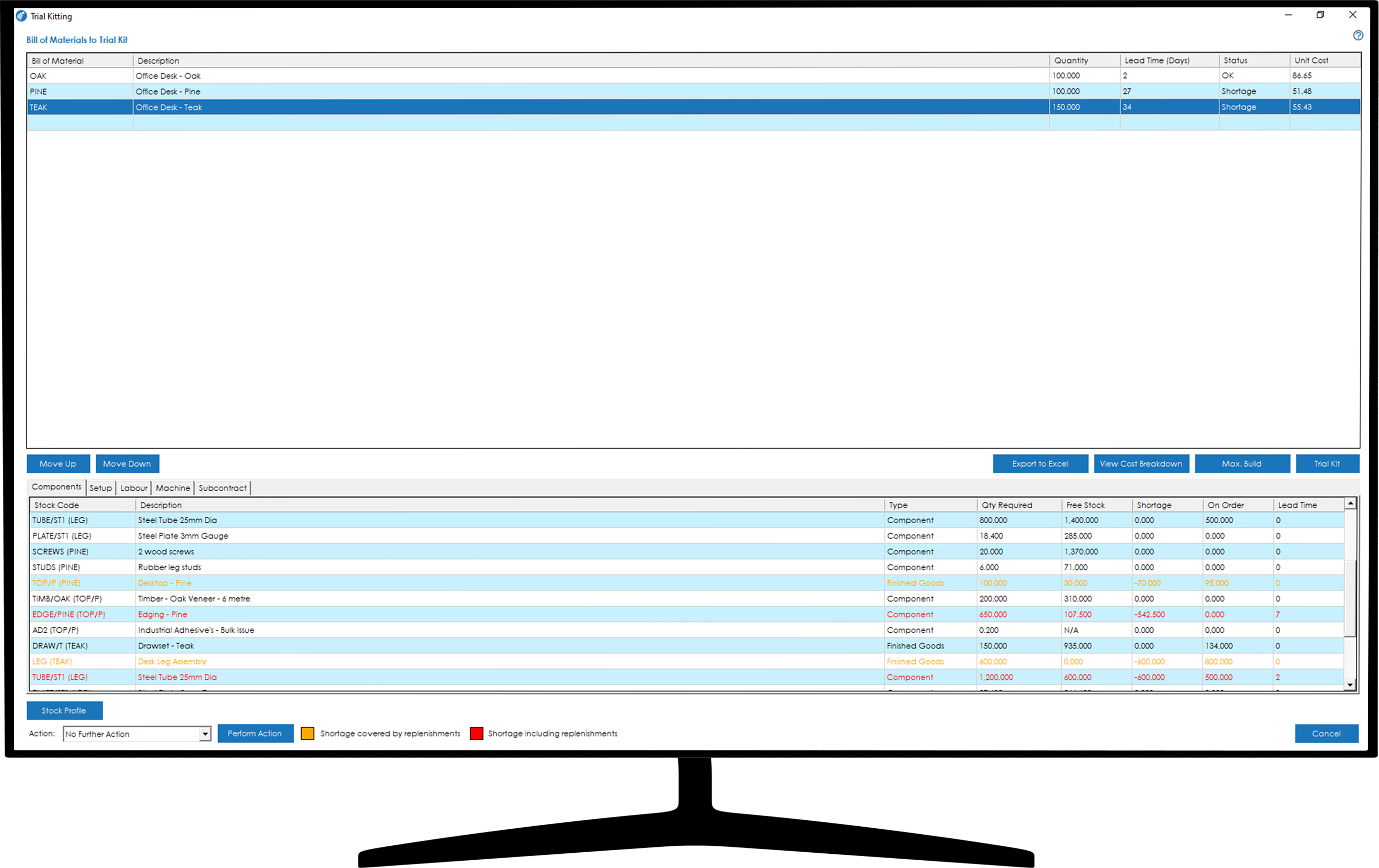

Trial Kitting

Trial Kitting provides you with an overview for the items you may wish to build, checking for shortages.

Easily raise works orders and purchase orders for several jobs, ensuring manufacturing and purchasing costs are most efficient.

View labour, machine, setup and subcontract requirements for complete transparency.

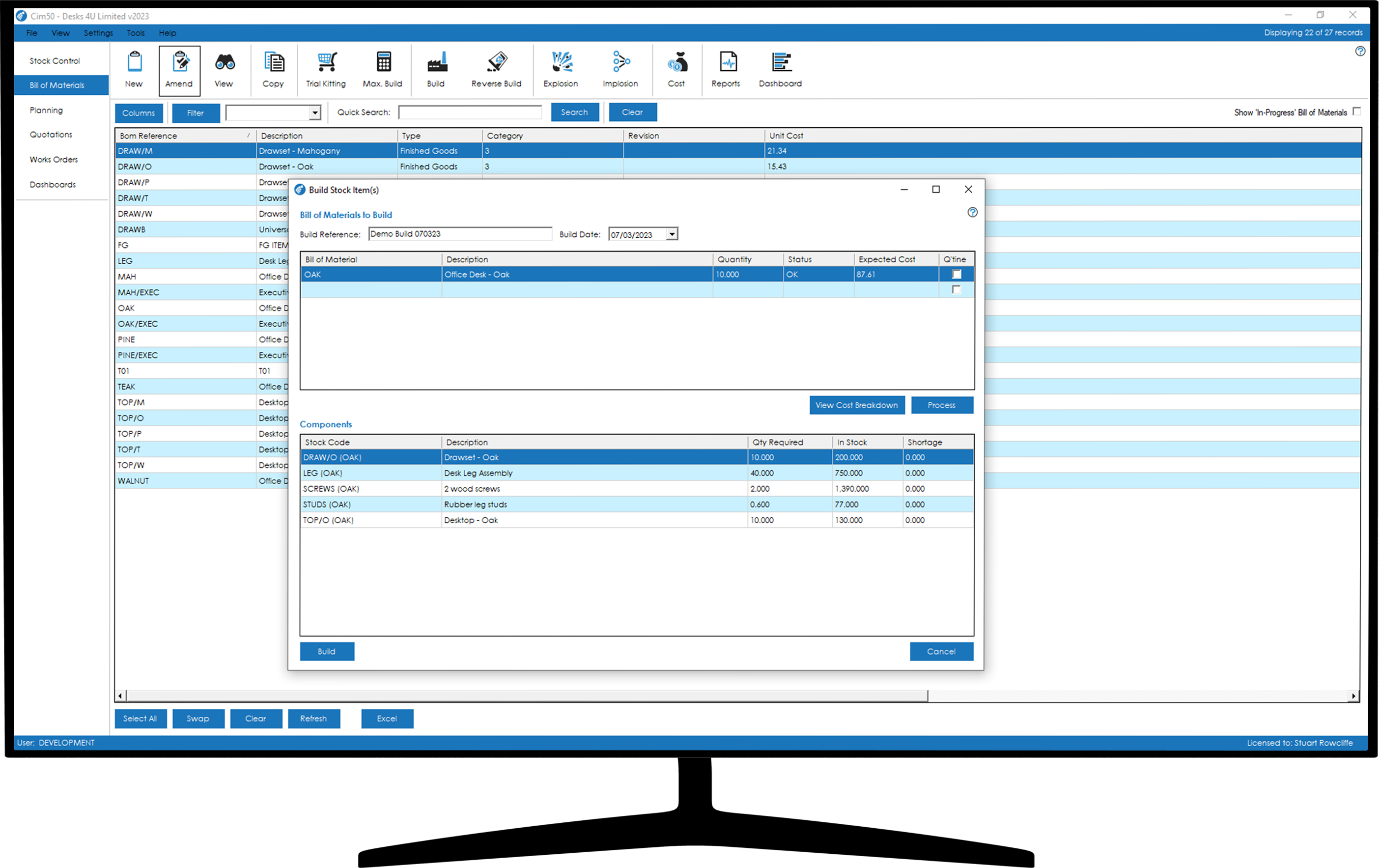

Build

Carry out BOM Builds to quickly transfer component items out of stock and transfer the finished goods into stock.

Build multiple items simultaneously, with common components being considered when calculating any potential shortages.

Finished items are booked into stock with production costs included.

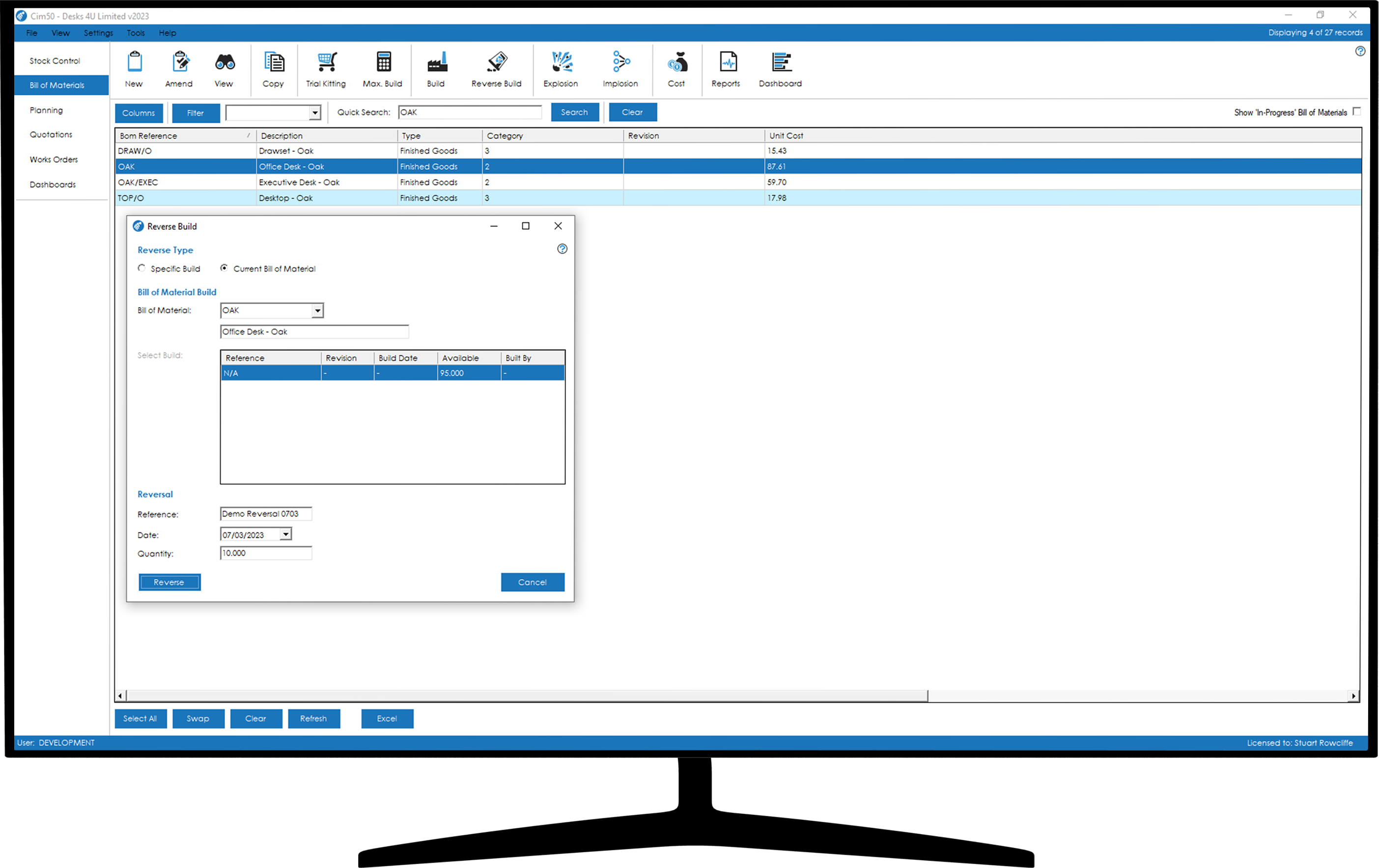

Reverse Build

The Cim50 reverse build functionality enables you to easily reverse a specific processed BOM build, or disassemble the finished item based on the current bill of material components.

Explode your components back into stock with accurate costs, allowing for variances and the possibility that not all components could be reserved into stock.

Explosion/Implosion

View a complete breakdown of the sub-assemblies and component items required for a finished product, presented in an easy to read tree-grid view.

Similarly, implode a component item to explore which assemblies it is used within. Drill in to further information for greater visibility.

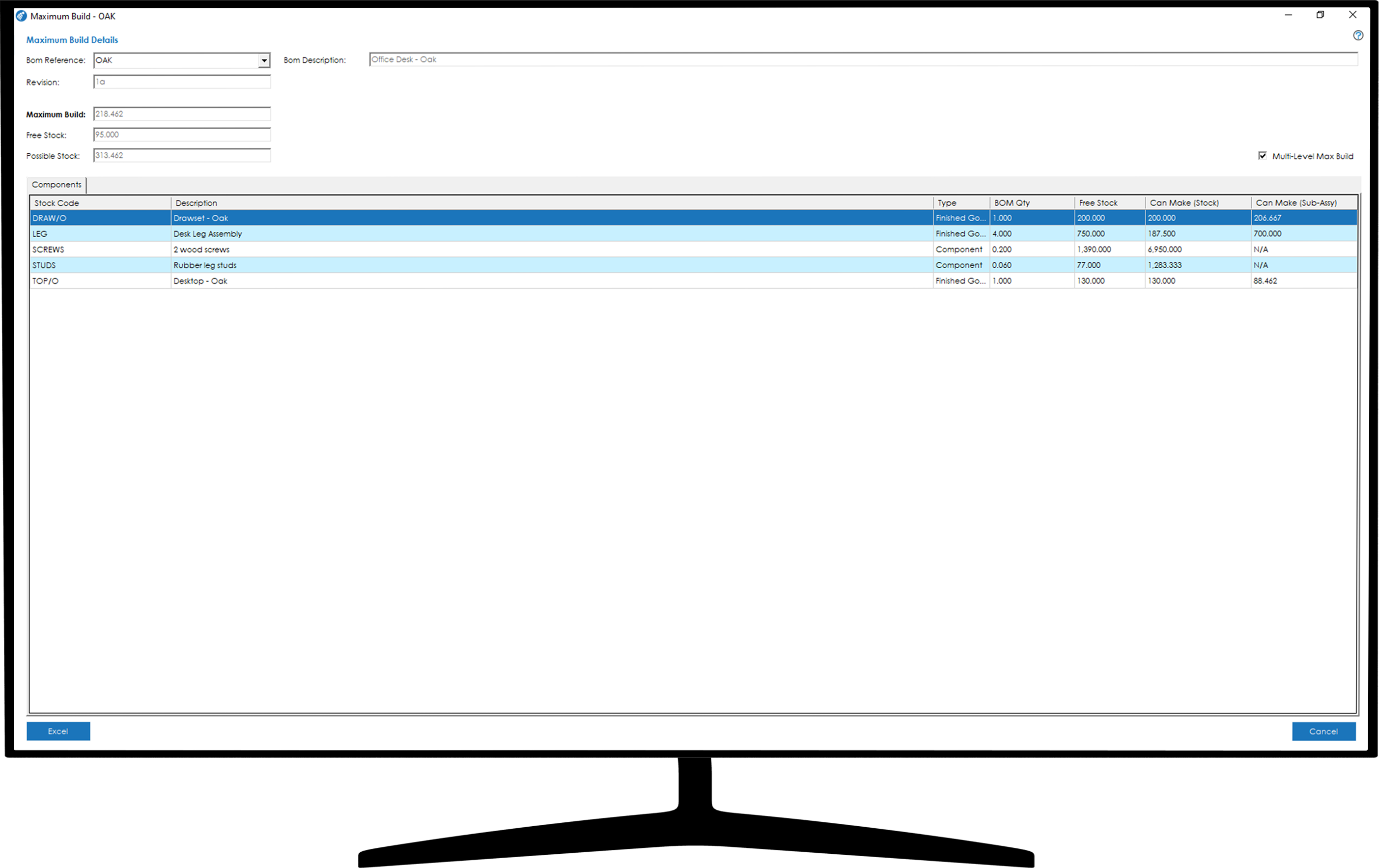

Max Build

Utilise the Cim50 Maximum Build functionality to quickly and easily see how many of a finished item or sub-assembly you could produce based on current stock figures.

The system can calculate 2 maximum build quantities for a manufactured item. The first assuming you only consumed stock that is currently available, or, alternatively it can calculate the maximum build quantity assuming you were to build sub-assembly items based on their own component availability.

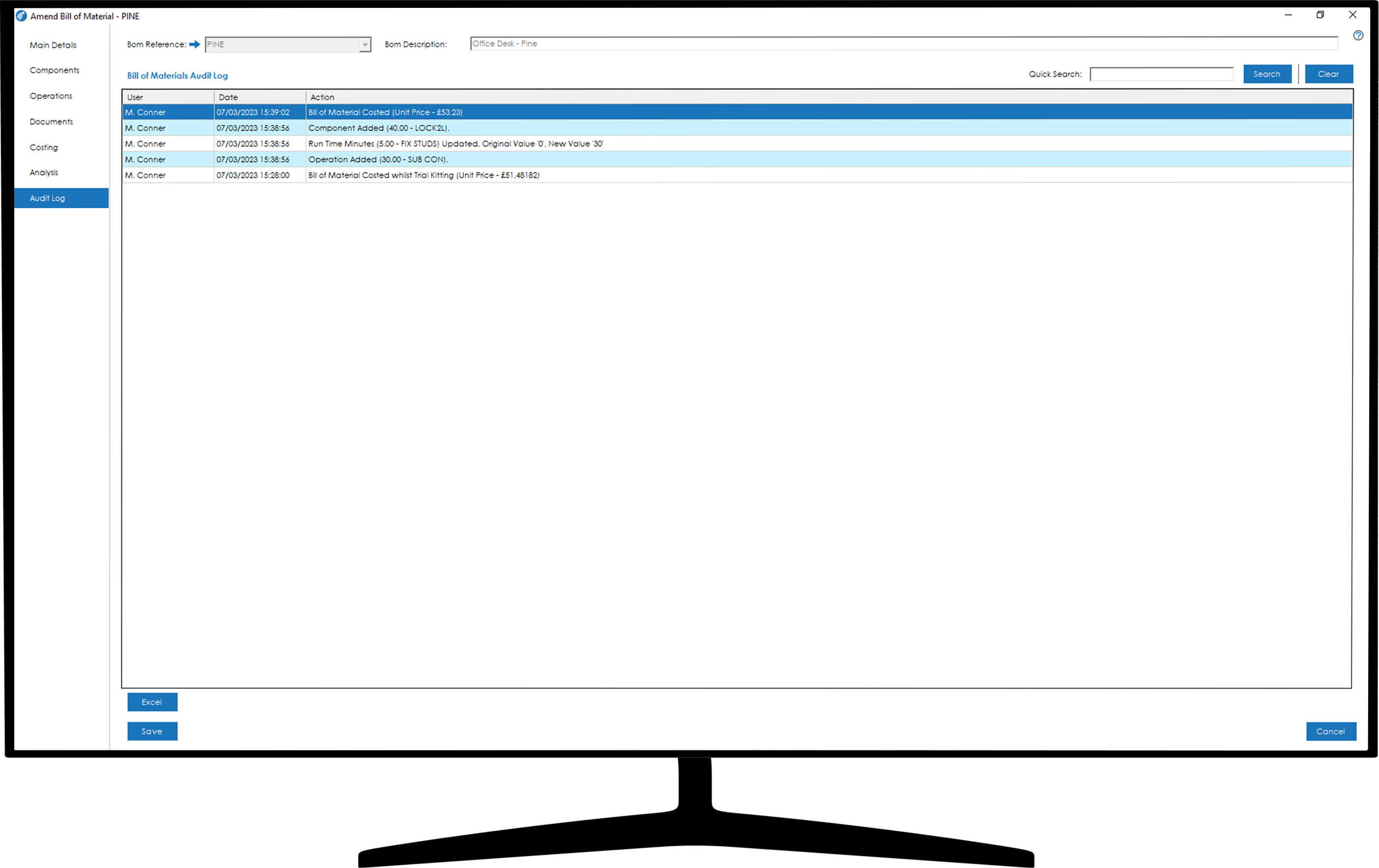

Audit Log

With Cim50 Bill of Materials, the audit log allows you to check for amendments and ensure your bill of materials are accurate. Track any changes made and by whom, with the option to search for specific amendments.

Export the audit log to Excel for further analysis.

Additional Bill of Materials Features

Features | Description |

|---|---|

Operation Components | Assign components to a relevant operation and print on the appropriate paperwork to ensure components are only allocated when needed. Furthermore, the Planning module will ensure associated components are available just-in-time for the start of the operation, rather than the start of the job itself, useful for jobs that span a long period of time, where some components are not needed until the latter stages. |

Subcontract Costing | Setup Bill of Materials with multiple sub-contract suppliers. Define price/quantity breaks and subcontract process times. Accurate costing ensures the finished item cost includes the costs for any subcontract processes. |

Drawings & Attachments | Cim50 includes a comprehensive Drawings Register, which can then be associated with one or more Bills of Material and subsequently appearing on associated Works Orders.

You can also attach any document type to a Bill of Material, which again will appear on any associated Works Orders created from the BOM. These Drawings/Attachments can then be opened directly from the BOM or Works Order in Cim50. |

Resources | Define multiple Labour, Machine and Tool resources in the resources register and utilise those resources on Bill of Materials. Flexibility on the BOM enables you to configure the resource times and costs against each operation, allowing for accurate costing and production planning. |

Operations | Define multiple In-House or Subcontract Operations on a Bill of Material. Configure the operation to include operator instructions, expected processing times and costs. |

Reporting & Dashboards | Utilise the standard reports and dashboards to see build volumes and values by week, where BOMs have higher costs than suggested selling prices along with component where used reports and costing analysis. |

Archive | Archive Bills of Material functionality enables you to keep your live data tidy whilst retaining historical Bill of Material information, which can be reinstated should an obsolete item become active again. |

Unlimited Components & Levels | Ability to create multiple level bill of materials with unlimited components. |

Cim50 Bill of Materials FAQs

Can’t find the answer you’re looking for? Contact Us

No, once you have Cim50 you would create and maintain Bill of Materials within the Cim50 system.

If you currently use Sage 50 BOMs we have tools and imports available to migrate those BOMs into Cim50 as part of the implementation process.

Yes. Every time you carry out a BOM costing in Cim50, the system stores a full breakdown of that costing session against the BOM, enabling you to look back at any point in the future and interrogate historical costs.

You can only have 1 version of a Bill of Material in Cim50.

The Bill of Material audit log functionality retains full details of all changes made to the Bill of Material since it was created. Coupled with revision numbering, this log enables you to see all changes made between revisions.

Works Orders inherit the current revision number from the Bill of Material at the time they are created.

If full version control is required, this is available using Cim200 (and Sage 200).

There is no limit to the number of BOM levels you can have in Cim50.

There is no limit to the number of components you can have on any individual BOM.

Sage do not recommend having more than 20,000 product records in total in the Sage 50 Accounts system. If your business has more than 20,000 product records in total, we would recommend considering Sage 200 with our Cim200 add-on.

Yes. With the Cim50 disassembly functionality, you can take a finished product out of stock, putting the component items from the Bill of Material back into stock. The process enables you to adjust the specific component quantities that are placed into stock, as well as giving you control over cost variances.