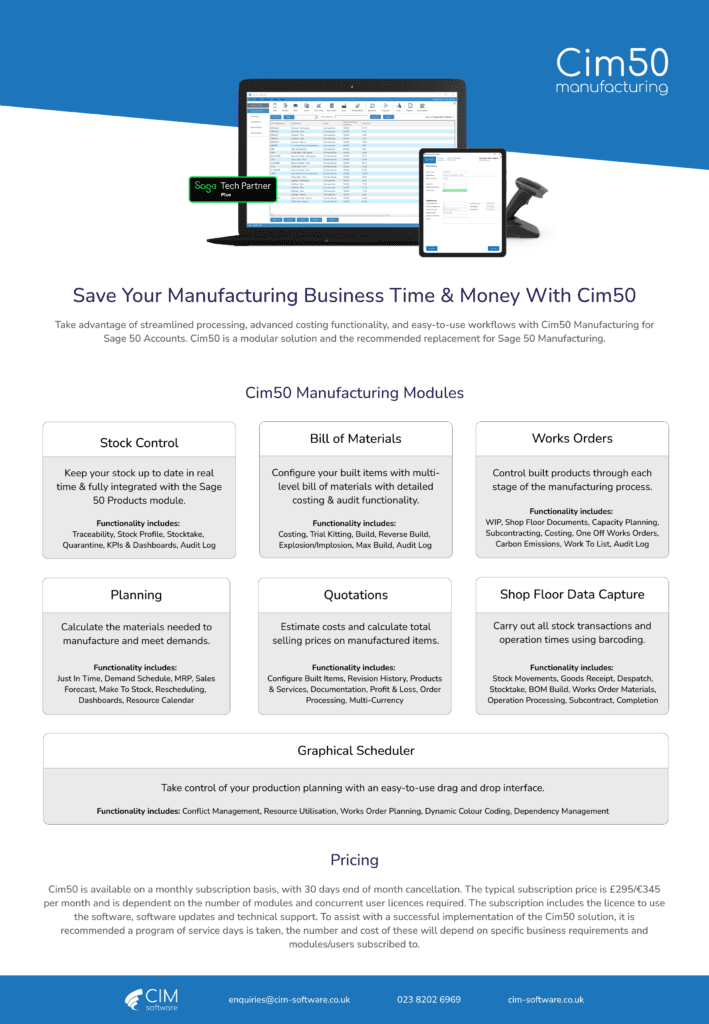

Cim50 – Planning

Delivering Just in Time Planning to Meet Deadlines, Reduce Stock Holding & Improve Cashflow

Manufacturing Planning Software - MRP

With Cim50’s Planning module, integrated with Sage 50 Accounts, calculate the materials needed to manufacture products and meet customer demands.

Ensure Demand is met from across Sage 50 and Cim50

Cim50 Planning reads from sales orders, sales forecasts, works orders, reorder levels and make to stock to verify that demands can be satisfied.

Track Shortages and Replenishments

Identify purchase and manufacture recommendations based on current demand versus stock on hand and outstanding orders.

Improve Cashflow with Rule Based Recommendations

Set up individual stock items with pre-requisites such as reorder rules and lead times to only buy and manufacture what you need, when you need it.

Included In Our Cim50 Planning Module

-

Just In Time

- Demand Schedule

- MRP

- Sales Forecast

- Make To Stock

- Rescheduling

- Dashboards

- Resource Calendar

Just In Time

Cim50 is a “Just-in-Time” manufacturing system. The planning module recommends placing orders with suppliers and starting production so that they arrive exactly when they are needed, minimising your stock holding levels.

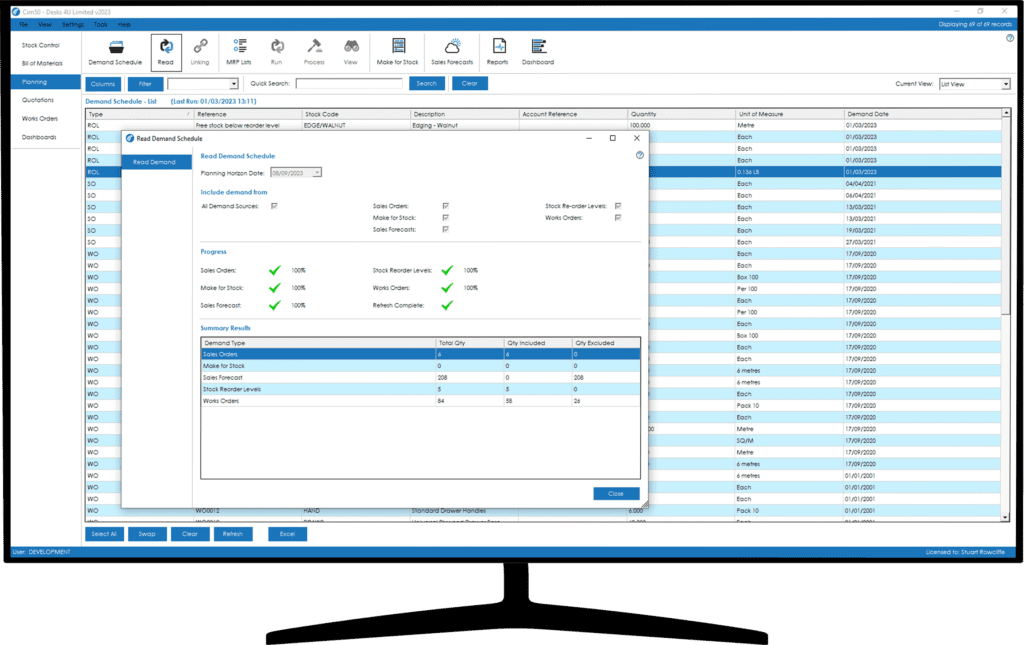

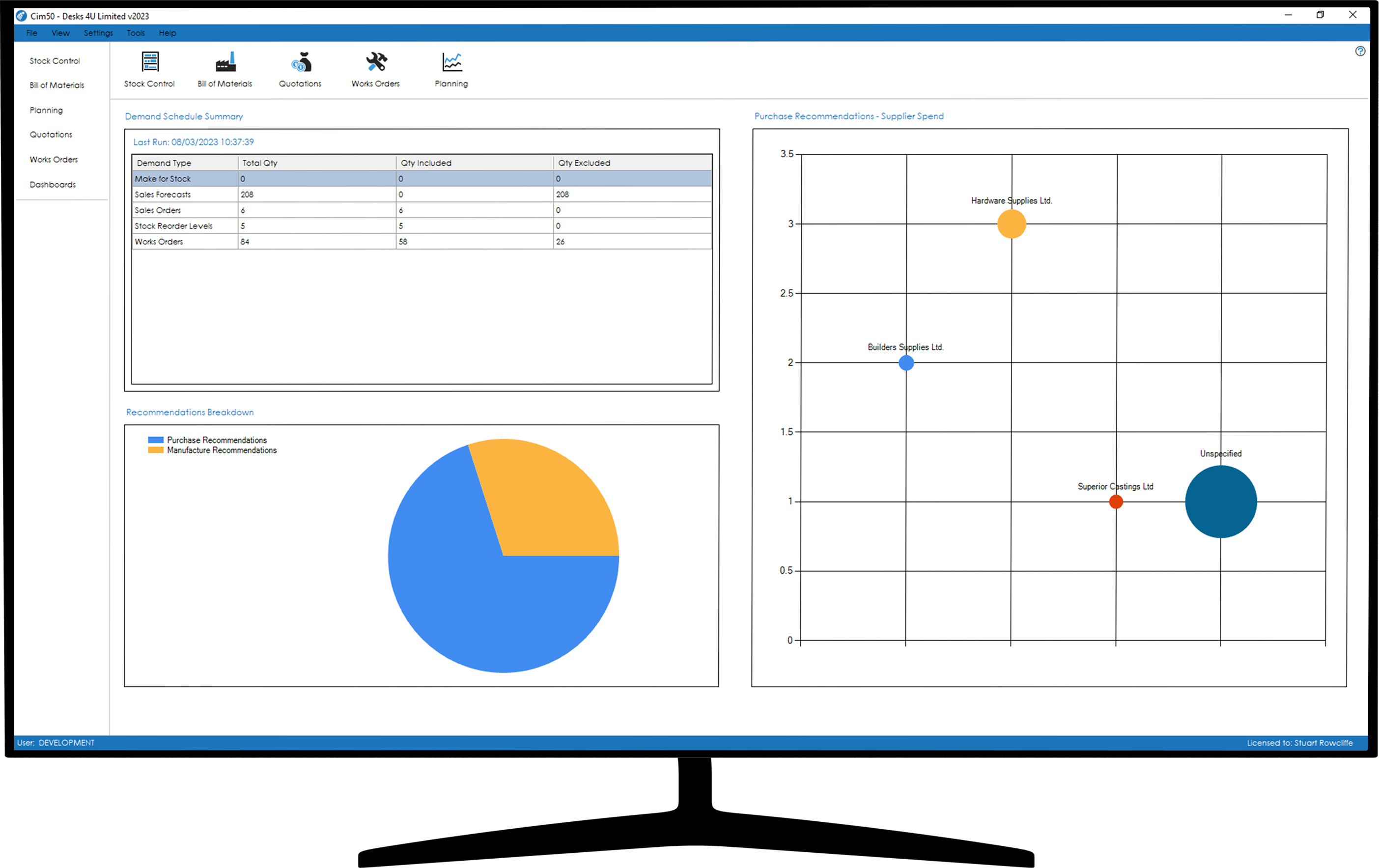

Demand Schedule

The Cim50 Demand Schedule is a complete list of all the demands that the MRP process will factor when calculating its recommendations.

You can filter the items that are to be included in the demand schedule by type of demand, along with scheduling the demand schedule to process automatically out of hours if required.

.

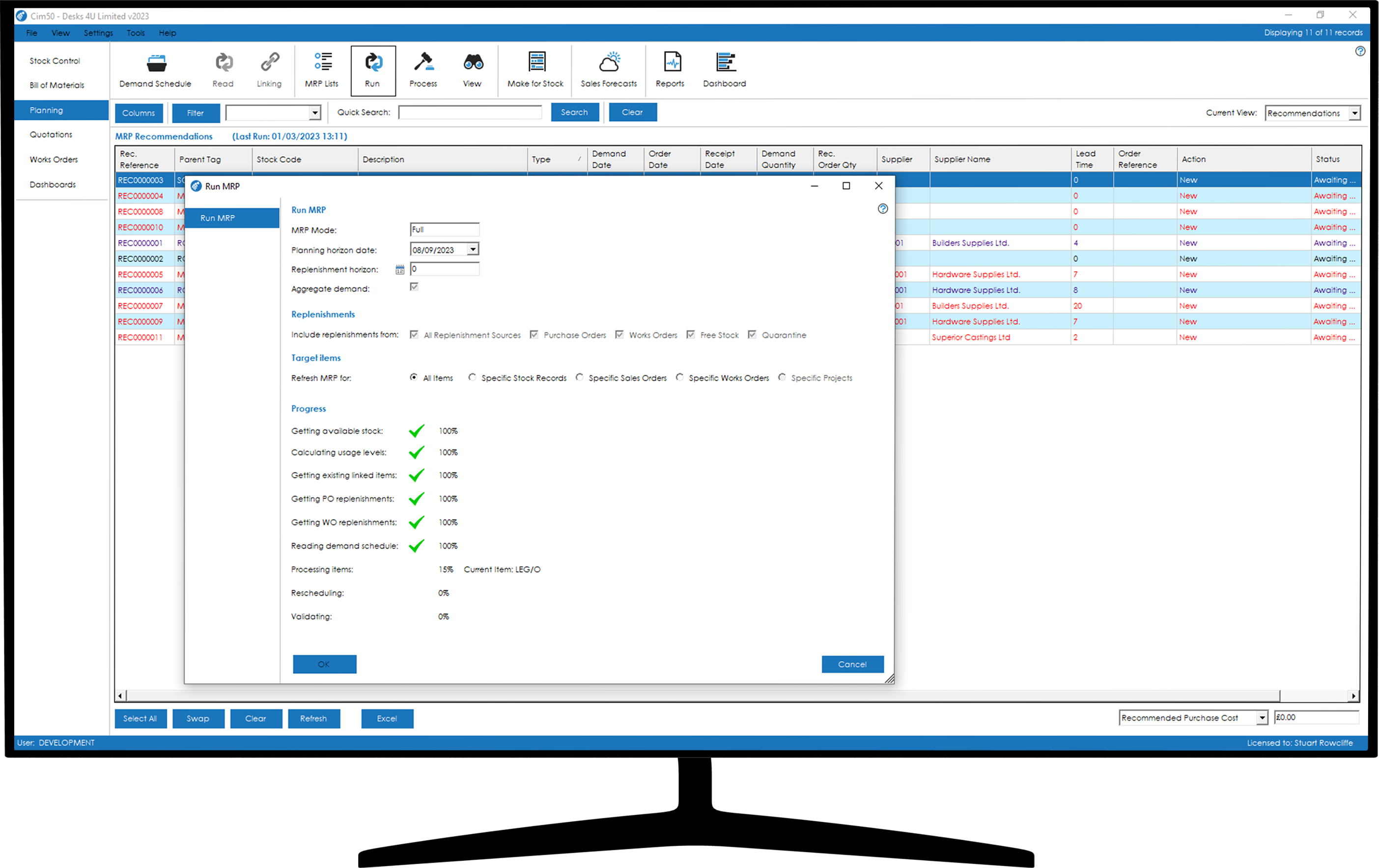

MRP

MRP (Material Requirement Planning) reads through all the demands on the demand schedule and then offsets available stock and replenishments against those demands to determine a list of demands that cannot currently be satisfied. It will then generate a list of rule-based recommendations to purchase components and manufacture sub-assemblies and/or finished goods in order to ensure all demands can be met.

To save rekeying data, recommendations can be actioned to create purchase orders in Sage 50 Accounts and Works Orders in Cim50.

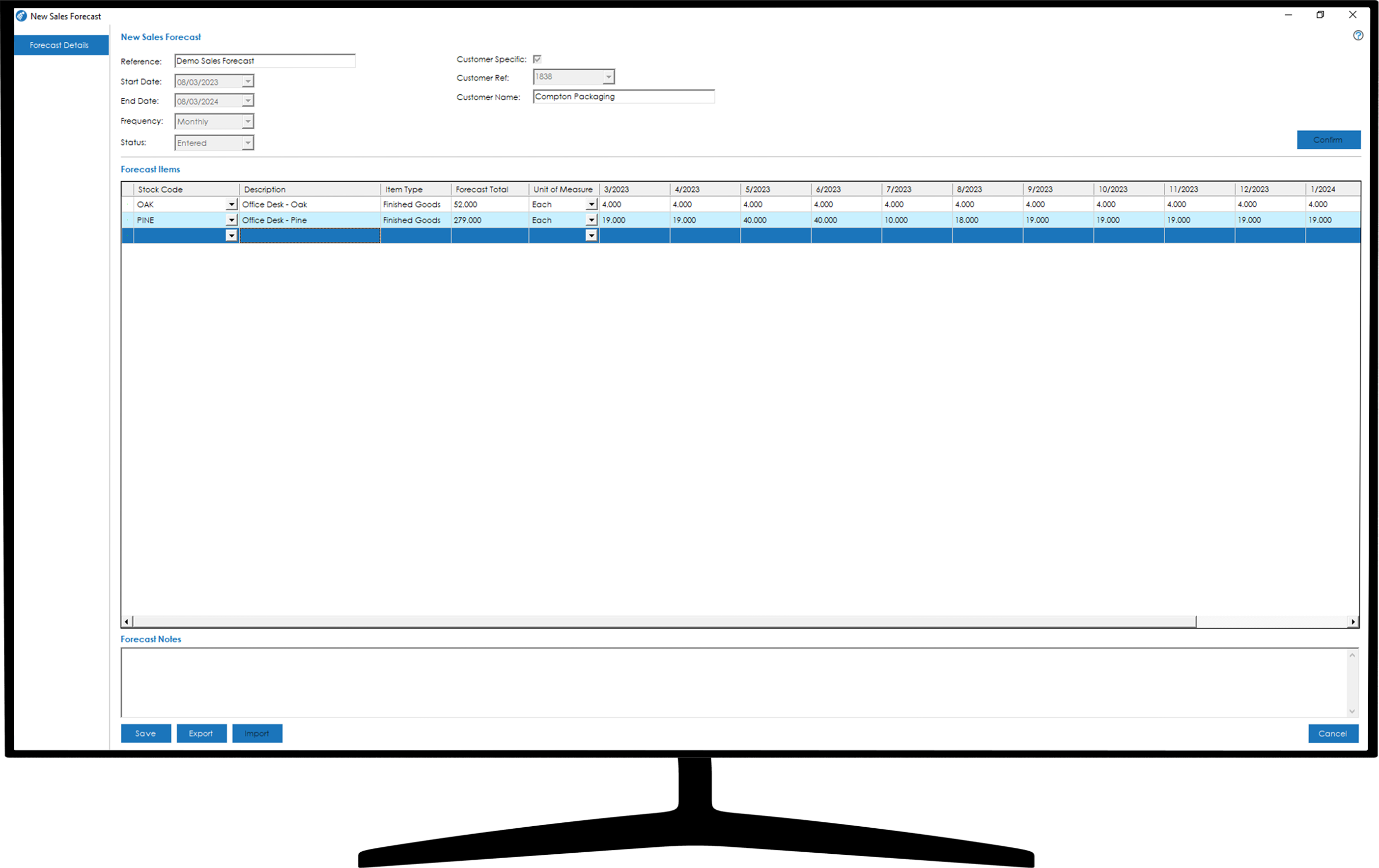

Sales Forecast

Cim50 gives you the ability to create sales forecasts on a daily, weekly, monthly, or quarterly basis. Forecasts can be configured for specific customers or for any customer.

The planning system will read the sales forecasts and factor them into the calculations when considering upcoming demand and offset them.

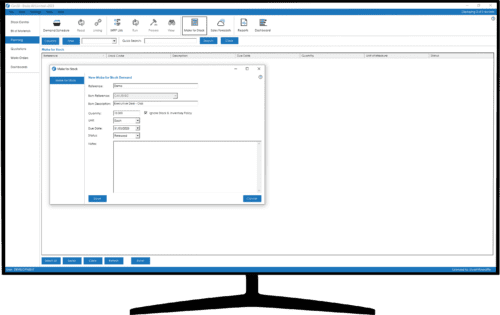

Make To Stock

Cim50 Make to Stock demands allow you to create ad-hoc demands for items that the planning system will factor into its calculations and ensure you have the specified quantity of that item available in stock on the desired date.

Rescheduling

When the MRP process has completed its calculations, it will interrogate all existing replenishments on the system and determine if the date they are due to be received is still relevant, or if they are still needed at all.

If they are still needed but the due date on the demand they are needed for has changed, it will recommend rescheduling those purchase/works orders so that they are receipted just-in-time for the updated demand due date, freeing up your cashflow and avoiding stock being sat on a shelf for any longer than needed.

Dashboards

Utilise the dashboard functionality to see the summary from the latest demand schedule run, a breakdown of your MRP recommendations, along with a bubble chart showing suggested supplier quantity and spend.

Resource Calendar

Not all resources are available for the same amount of time each day, whether that be due to shift patterns, part time workers, or machine maintenance.

Cim50 enables you to define individual working calendars for each resource, with the system utilising those individual calendars to determine production planning times and completion dates.

Additional Planning Features

Features | Description |

|---|---|

Schedule Planning | Cim50’s Demand Schedule Refresh and MRP can be scheduled to run out of hours as and when needed. |

Aggregating Demand | You can configure each stock item with individual aggregation settings, with options to aggregate by a specific number of days, by calendar week or calendar month. All demand that falls within those aggregate buckets will be combined, streamlining your MRP recommendations and ordering/production processes. |

Supplier Minimum Spend | You can define minimum supplier spend figures in Cim50 and the planning system will warn you if a Purchase Order you are about to raise does not meet those minimum spend requirements. |

Firm Planning Periods | Utilise Firm Planning Periods to ensure that the Planning system does not recommend altering production plans within a specified timeframe. |

Overdue Demand/ Replenishments | The system can treat overdue Demands and Replenishments as expected to happen today, enabling the system to plan accordingly, whilst maintaining the ability to track KPIs for performance reporting and cutting down on potential admin overhead. |

Tags & Links | Easily track and identify what replenishments will be used to satisfy which demands via the simple yet powerful tagging system. Convert tags to firm links if required at the touch of a button, so the planning system does not re-tag a replenishment unexpectedly. |

Stock Profile | The Stock Profile screen is a powerful tool enabling you to see a complete overview of your stock position for an item at a given date.

From one screen you can see your current stock position, what orders are awaiting receipt from suppliers or works orders, what outstanding customer orders are on the system, what stock is in quarantine, giving you all the information you need to make an informed decision. Furthermore, real-time and planning projections are available, showing you the expected position of stock into the future. |

Safety lead times | Define individual purchase or production safety lead times within the MRP software to ensure you can meet your customer expectations regardless of any potential delays. |

Define Make-To-Stock Items | Define make-to-stock items for specific dates and quantities. |

Cim50 Planning FAQs

Can’t find the answer you’re looking for? Contact Us

MRP stands for Material Requirements Planning.

Jobbing production is a method of production where each order is specifically produced to your customers specific requirements.

With Cim50, you can specify which stock records should be processed in this way, giving you flexibility to produce certain items to order.

Yes, once the MRP system has generated a list of recommendations, you can interrogate the purchase recommendations and raise purchase orders directly from the recommendations lists.

Yes, once the MRP system has generated a list of recommendations, you can interrogate the production recommendations and raise works orders directly from the recommendations lists.

In simple terms, MRP will produce a list of production and purchase recommendations that will ensure you can fulfil your customer’s orders.

It reads through every demand on the system, interrogating the dates for each of those demands (sales orders, sales forecasts, production demands), then offsets the demands against available stock and replenishments (purchase orders, works orders) before determining what demands cannot be satisfied by those replenishments.

It will then apply planning rules to the shortage items to produce the list of recommendations, taking into account purchase and/or production lead times.

The MRP system bases all its decisions on customer and production due dates. If an order is at risk of not being fulfilled on time, it will be highlighted on the MRP list view. Similarly, if the system is confident that an item will be late, that too will be highlighted (the colours are customisable) so that you can quickly and easily identify if everything is going to be delivered on time.

Cim50 is a “Just-in-Time” manufacturing system. It will recommend placing orders with suppliers so that they arrive exactly when they are needed, minimising your stock holding levels.

Furthermore, the Rescheduling functionality will recommend pushing back supplier purchase orders if the demand for which they are needed is delayed.

All designed to free up your cash flow, and not tie it up in stock sat on the shelf.